SUPERINKS team will visit FESPA 2023 exhibition

FESPA 2023 will be held on May 23-26, 2023 at the Munich Exhibition Center in Germany.

The SUPERINKS team will visit the FESPA 2023 exhibition and look forward to meeting you.

FESPA 2023 will be held on May 23-26, 2023 at the Munich Exhibition Center in Germany.

The SUPERINKS team will visit the FESPA 2023 exhibition and look forward to meeting you.

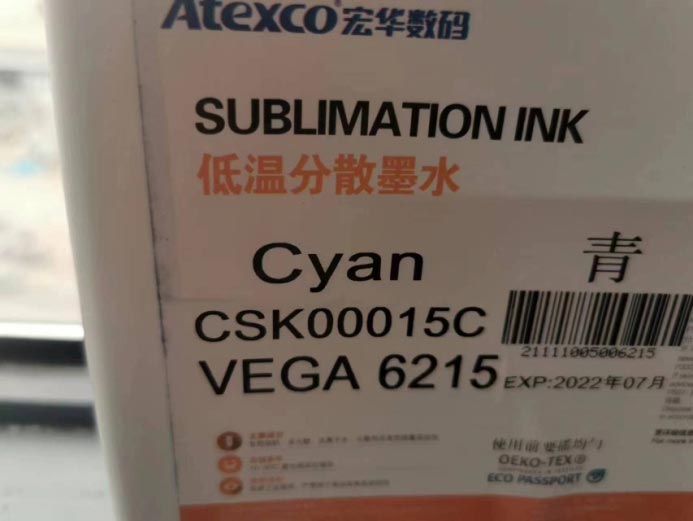

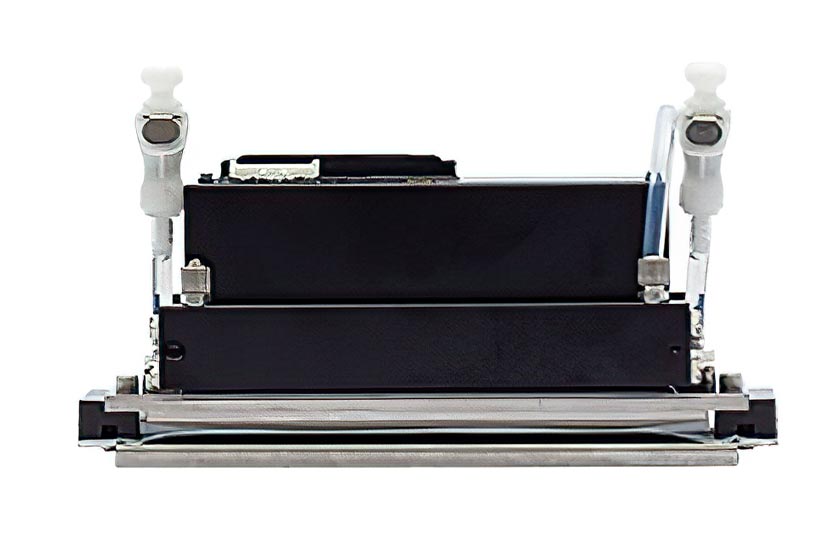

Until April 11, 2023, Atexco printer company released 4 types of sublimation ink for their Kyocera print heads. We use the Kyocera printhead Atexco printer and do these sublimation ink tests, see from the “dry speed”, “picture resolution”, “fluency”, and “color density”, etc to identify the difference.

And you can see video of SUPERINKS sublimation ink tests for Kyocera print heads on Atexco printer here. https://youtu.be/J3Yajjs89m0

SUPERINKS sublimation ink, can stay 1 hour without printing while printer turned on, the dry speed slower than CSK00011, while keeping the highest resolution for the pictures. One of our customers said: Ink dry slower, after one night, no need clean, ink density higher, friendly to print head. And if you have this SUPERINKS sublimation ink model at hand, you can compare the smell, the smell is much less than “11”.

This Kyocera head Atexco printer, uses best in room temperature of 20-28 ℃ and humidity of 50-80%. And we test SUPERINKS ink at 35 celsuis and 45% humidity extreme environment, printing for 2 hours, still working fluently, as the video here: https://youtu.be/e2ARSkMrX5U

And we suggest to our customers, if you want the printing to be stable, and smooth for days and nights working, you can install a humidifier in your printing room, like this:

If you have more questions about Atexco Kyocera print head printers to discuss, welcome to communicate with us.

There are three traditional sublimation heat transfer printing techniques: silk screen heat transfer printing, gravure printing (copper plate, electric engraving) heat transfer printing, and offset printing heat transfer printing. Traditional sublimation heat transfer printing is characterized by plate printing.

Digital heat transfer technology is a new technology that combines traditional heat transfer technology and digital printing technology to print color images and patterns without plate making. It is characterized by the application of digital printing technology to print color patterns and images without plate making, which saves the process and cost of plate making, so it is suitable for the production and printing of personalized products. The technical feature of digital heat transfer printing is that digital printing equipment uses special heat transfer color printing ink and heat transfer printing paper. The original texture of the material will not be changed after the sublimation pattern is transferred, and the hand feeling and appearance are good. The earliest countries to apply this technology include the United States, South Korea, Italy, Switzerland, China and others countries.

Sublimation inks are mostly formulated from textile disperse dyes, other chemical additives and water. Due to its saturated color and good weather resistance, disperse dyes are widely used in textile printing and dyeing, and are still one of the main raw materials in the printing and dyeing industry so far. The traditional textile printing and dyeing industry has serious environmental pollution problems in the process of dyeing with dispersed pigments, and it is not suitable for small batch production. The emergence of sublimation inks has made up for this defect.

The world famous brands of digital sublimation inks are: Epson, JTeck USA, Sawgrass, InkTec, DuPont, MIMAKI, Sensient Inks, JETCOLOUR, Hilord, and Nazdar.

Active markets are: Asia (China, Japan, India, Korea), North America (USA, Canada, Mexico), Europe (Germany, UK, France, Italy, Northern Europe, Spain, Belgium, Poland, Russia, Turkey), South America and the Middle East and Africa.

How to distinguish whether a sublimation ink is good or not? We can confirm it from the following four dimensions.

The high-precision industrial production nozzle recognized by the market is: Kyocera-KJ4B QA

https://global.kyocera.com/prdct/printing-devices/inkjet-printheads/.

Dye-sublimation ink printing is used for polyester fabrics, not only for clothing, but also for interior decorative fabrics, and outdoor advertisements (banner advertisements, backlit box advertisements, etc.) and due to the environmental protection of dye-sublimation printing, it will replace Traditional printing, instead of more and more advertising printing. In the Chinese market, dye-sublimation inks have matured around 2014, can reach a storage time of more than 8 months, and can withstand the high and low temperatures of sea transportation. From 2018 to 2022, China’s sublimation ink will begin to show explosive growth. Starting in 2023, the cost and price of sublimation ink will drop, and it will continue to occupy a larger market. There will also be more and more Chinese sublimation ink factories going international and establishing branches in different countries.

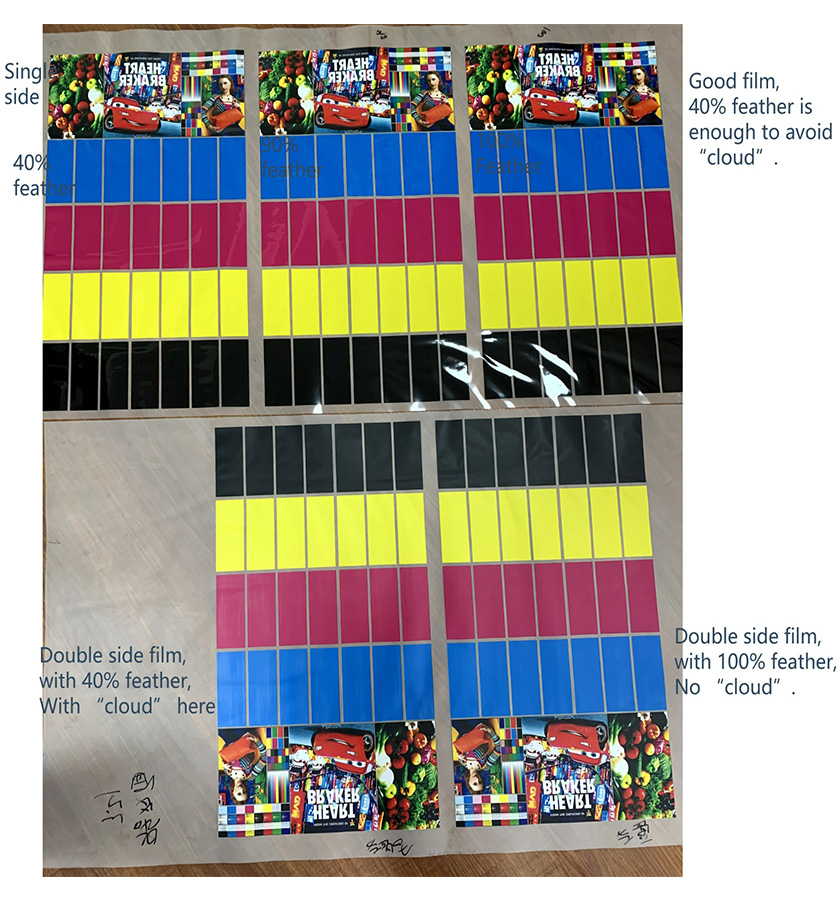

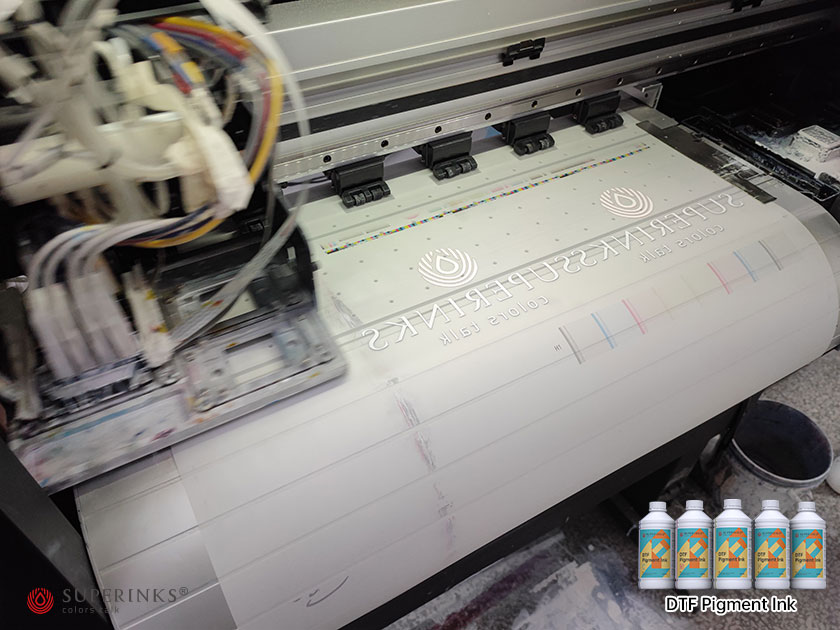

In DTF printing, for the problem of fast printing 4 heads, uneven color of printed pictures, like a “cloud”—especially magenta and cyan color.

Hosonsoft is currently the best motherboard for the Epson i3200 DTF printer, but it cannot avoid this problem, uneven color of printed pictures. So we need whole market technology to improve, we have to wait.

A). Use better DTF pigment ink, more fluent, higher density.

B). Use better film, thicker, better absorb. And the coating layer is more uniform, each ink drop absorbed well.

C). Lower the speed.

D). Use more “feather” settings, 40%, 80%, and 90%.

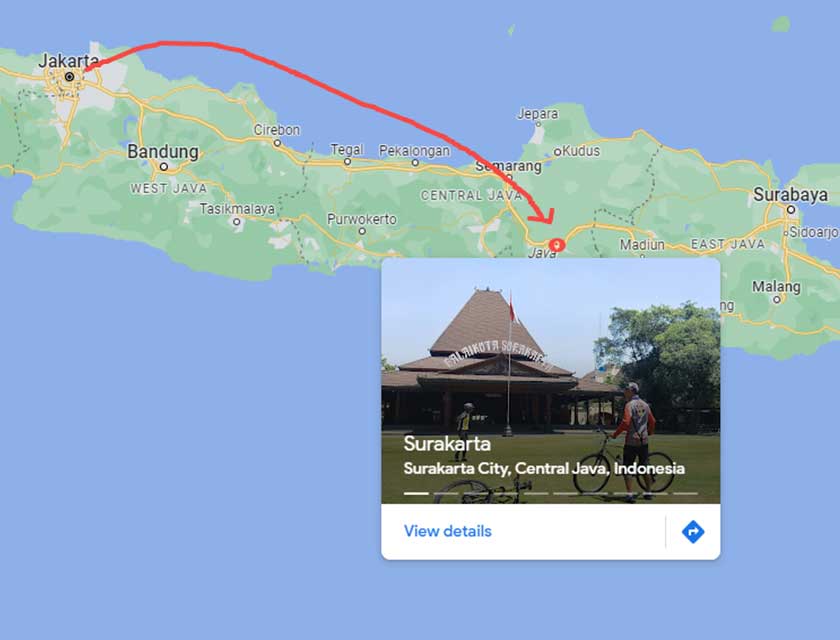

After 3 years of covid-19 lock, SUPERINKS flew to Indonesia from Mar 10-14,2023 and had a happy time with Binterjet company.

Our flight arrive Jakarta at Mar 10, and flight from Jakarta to Solo at Mar 11. Solo is a very beautiful place, located in Central Java, Indonesia, there are lots of green forest and farmland.

We visited Binterjet’s office and warehouse, SUPERINKS sent more support, and discussed deeper cooperation in 2023.

We visited representative Binterjet customers to provide support and advice.

After work, we drove to the top of the mountain with Hadi’s family, enjoying the beautiful scenery, eating natural food from the mountain, and had a great weekend.

Mar 13, we flight back Jakarta with Hadi, and visited their Jakarta office. Jakarta is a busy modern city, prosperous and full of energy.

The SUPERINKS team happily ended their trip to Indonesia.

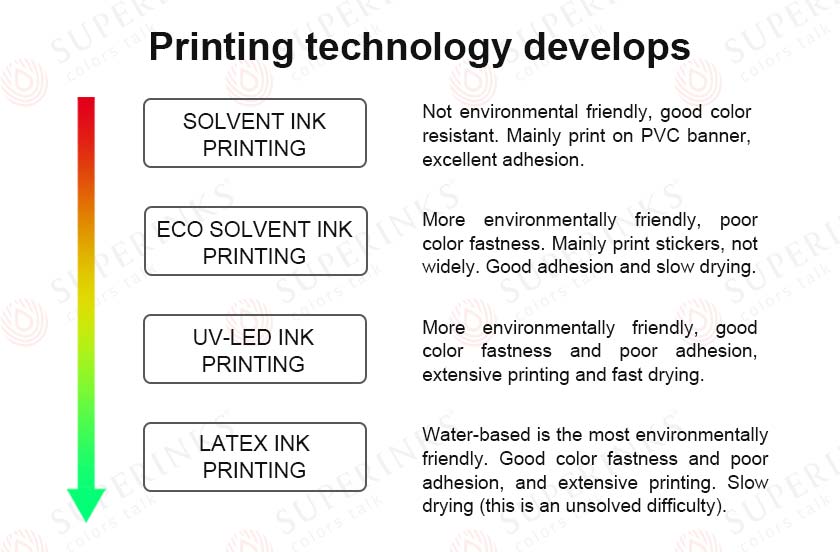

HP from the USA always leads the digital printing technology area, especially on AD signs, from hard solvent ink to UV-led ink printing, and then to latex ink printing. There are big steps between every step. The small step from solvent to eco solvent. Leads by Japan Market.

Each step of the printing technology develops with more environmental, wider applications.

On the other hand, sublimation printing for AD signs also has more application for its lighter, more eco, cheaper, better adhesion.

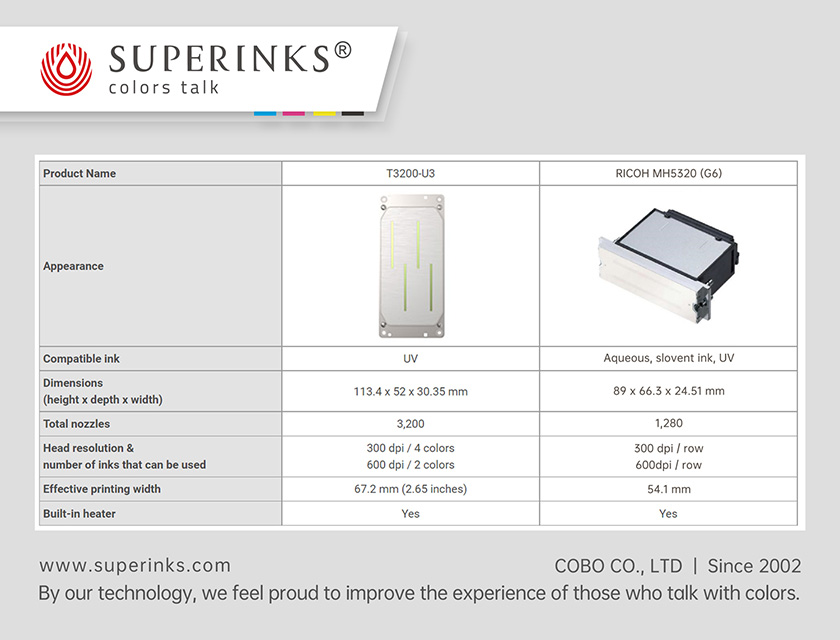

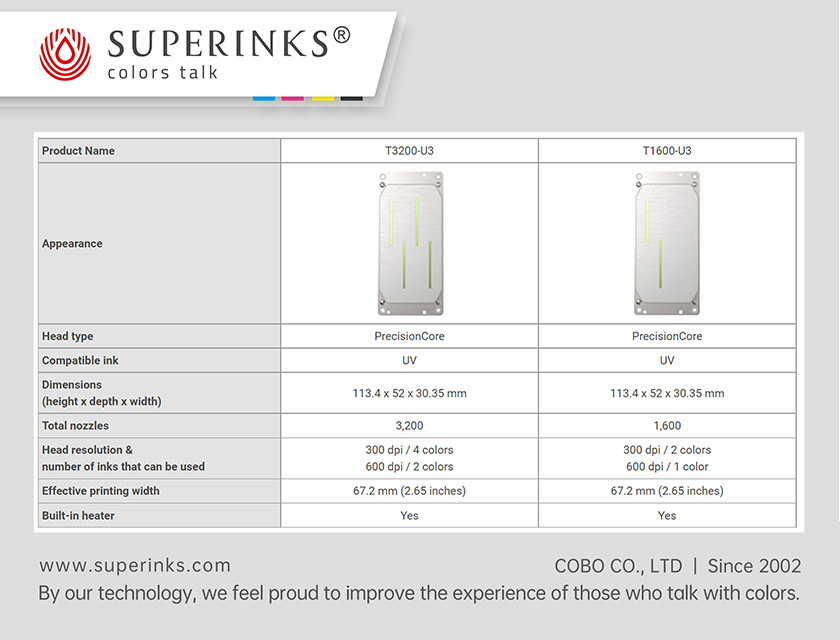

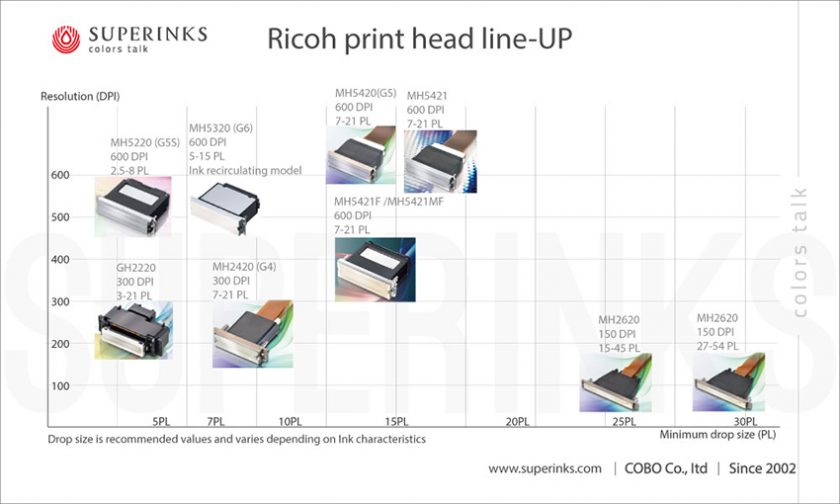

Epson T3200 and Ricoh G6 have started fierce competition in the market, but how do we look at the advantages and disadvantages objectively.

EPSON T3200 launched in 2021 with 4.8-5PL. Printer brands JHF, Docan, Flora, GZ, etc. have begun promoting flatbed UV equipped with the EPSON T3200.

The EPSON T3200 single-head production capacity is about 15-20 square meters per hour, and it supports 4 colors in one head, which is faster than Ricoh G6. But our technical department said that according to their experience, Epson print heads are easy to fly ink, especially when the temperature is low or the printing height is high. And Epson heads have less jet pressure than industrial heads.

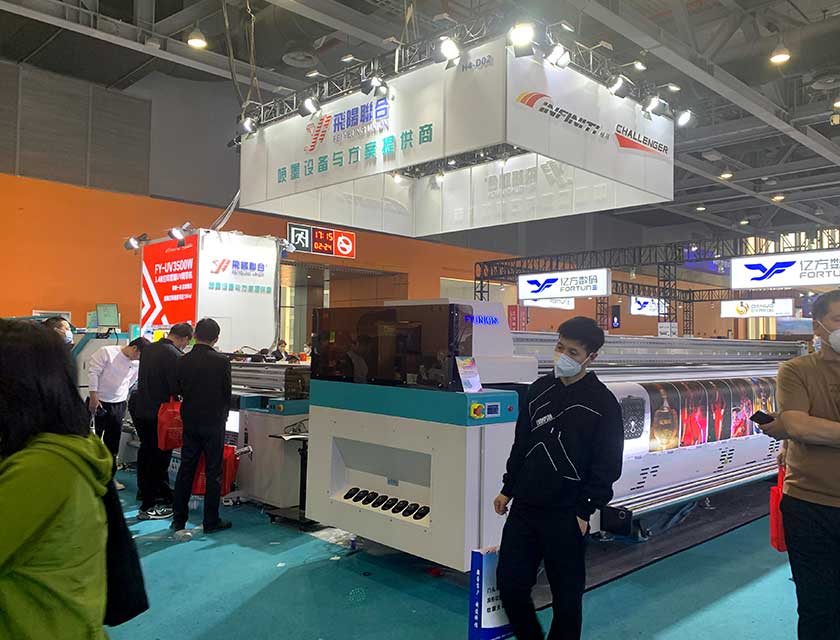

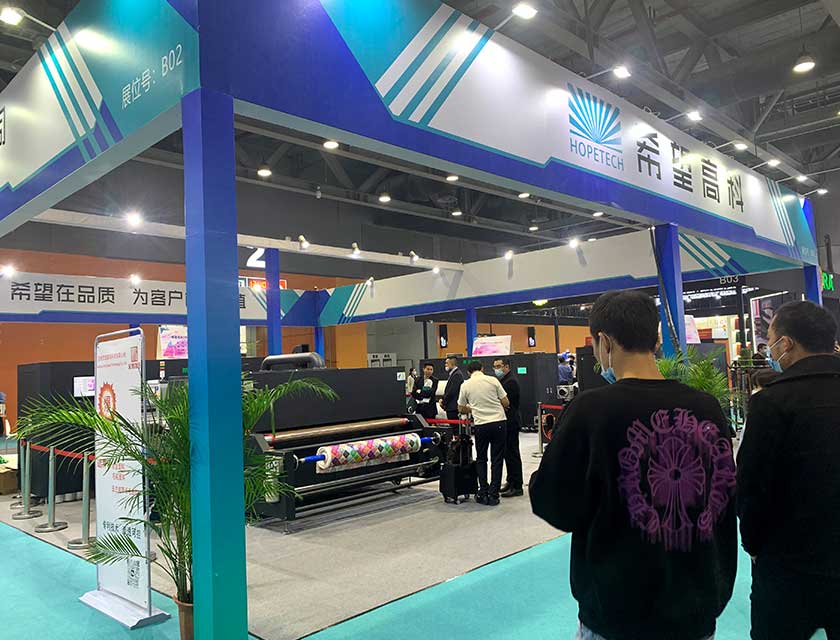

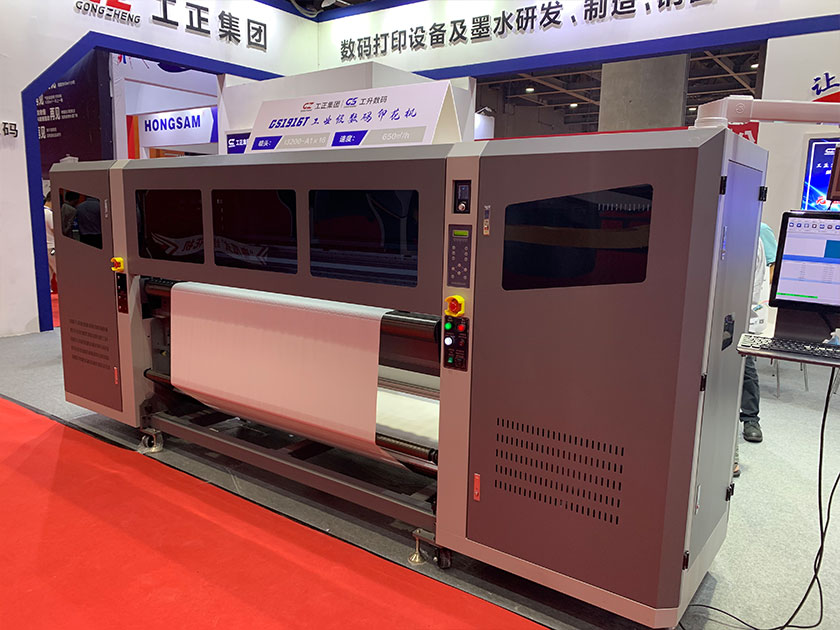

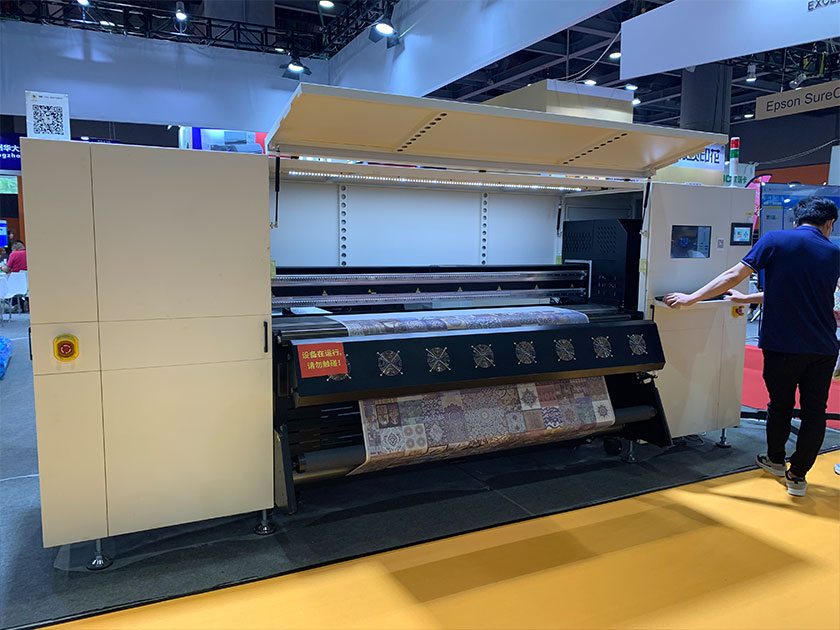

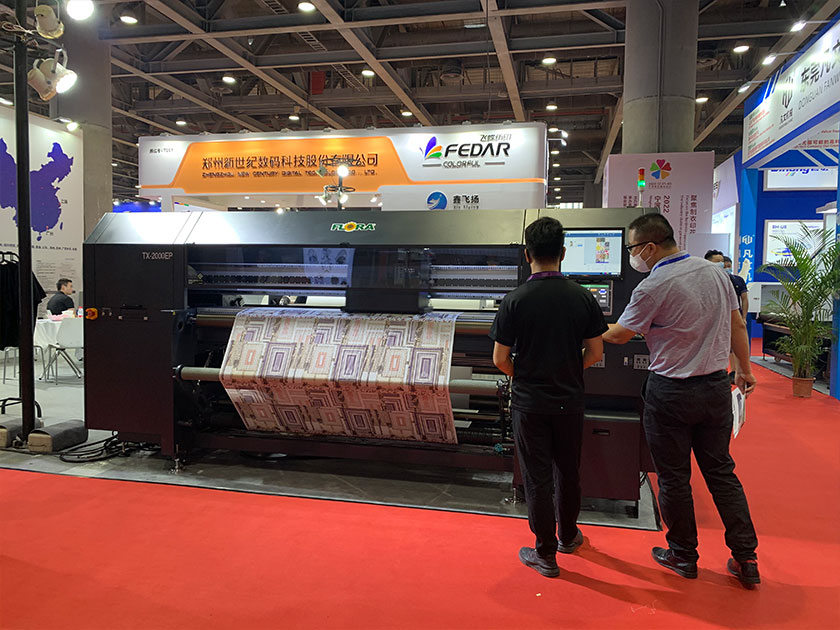

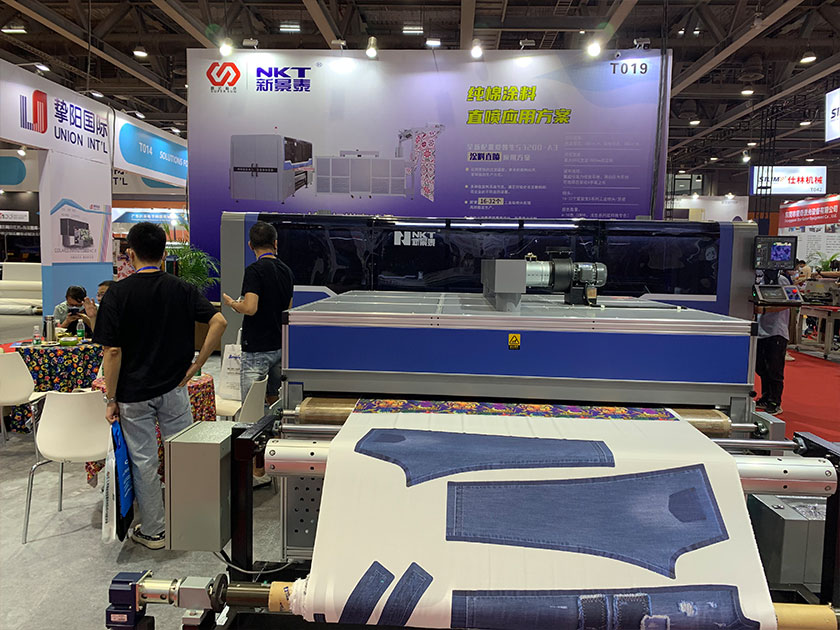

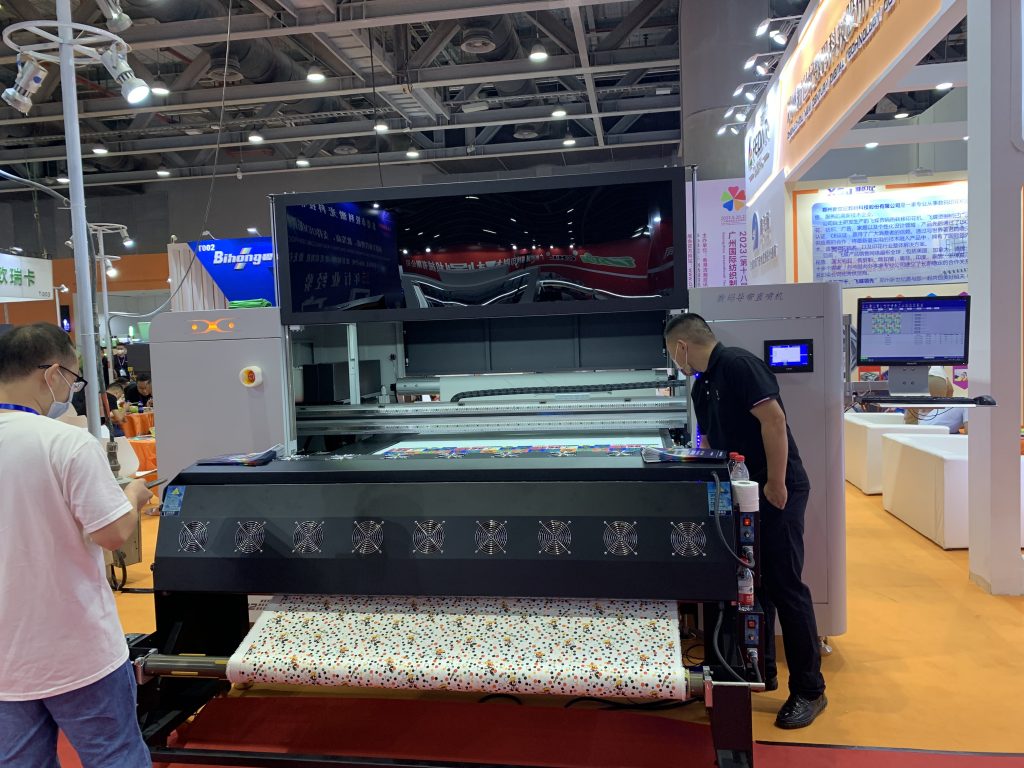

DPES 2023 Guangzhou Textile Printing Exhibition – the first textile printing exhibition in the opening year, showing the participation of nearly a hundred mainstream digital textile printing equipment manufacturers in China and the cutting-edge application of digital inkjet technology in the field of textile printing, digital direct injection, digital heat Sublimation, white ink heat press and supporting consumables are a one-stop platform for learning, communication and business in the global textile printing industry.

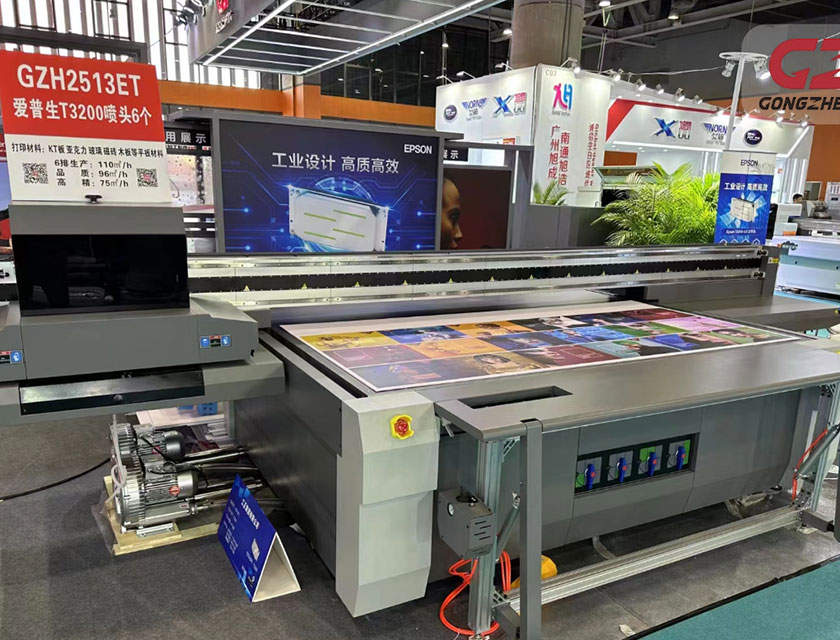

Which printer brands are promoting UV-led printers?

-Flora: Epson T3200 U3 (24-36 heads)

-GongZheng: T3200 U3 (Max 14 heads), Koncia 1024i/ 1024A

-Docan: Kyocera (8 heads); Konica 1024A (40 heads), Epson T3200

-Liyu: Konica 1024/ Ricoh G6 (Maximum 9 Rows 63 heads)

-Allwin: 1024I (4-36 heads)/ 1024A (4-24 heads)

Etc.

Which printer brands are promoting eco/ solvent printers

-GongZheng: Starfire 1024 25PL

-Wit-color: Starfire 1024 25PL

-SMT- Jet: Starfire 1024 25PL

-FY-union: Seiko 1024 HG and Epson i3200

-Allwin: Konica 1024i/512i

-Xkeda: Epson i3200-S1HD(4 heads)/ Epson i3200E1 (6 heads).

-Skycolor: Epson i3200

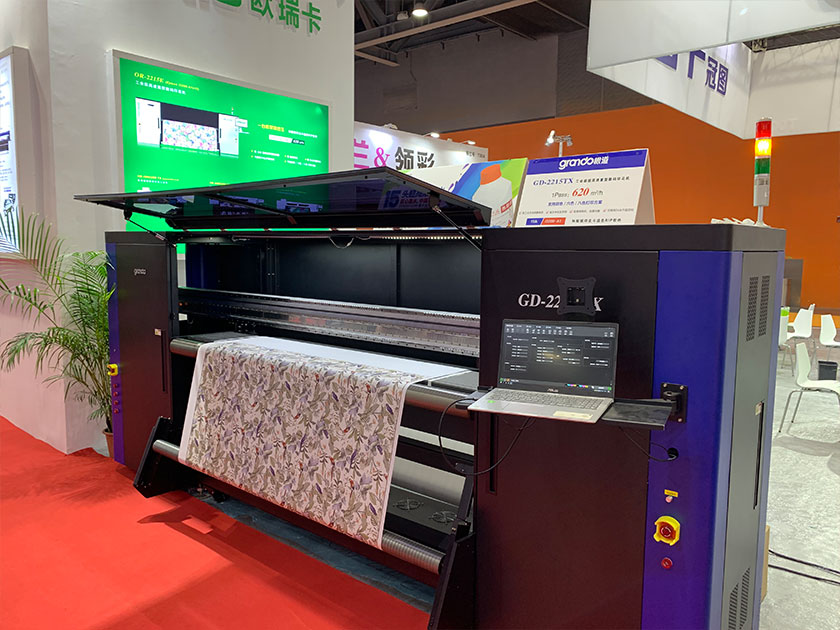

-Grando: Epson i3200

-Xuli: Epson i3200

-Xenons: Epson i3200

Etc.

Which printer brands are promoting sublimation printers?

Epson S3200 A1 Dye Sublimation Printer:

-Flora: (Epson S3200-A1 24 heads)

-Xkeda

-Hopetech

Etc.

Epson I3200 A1 Dye Sublimation Printer:

-Coltex

-Flora

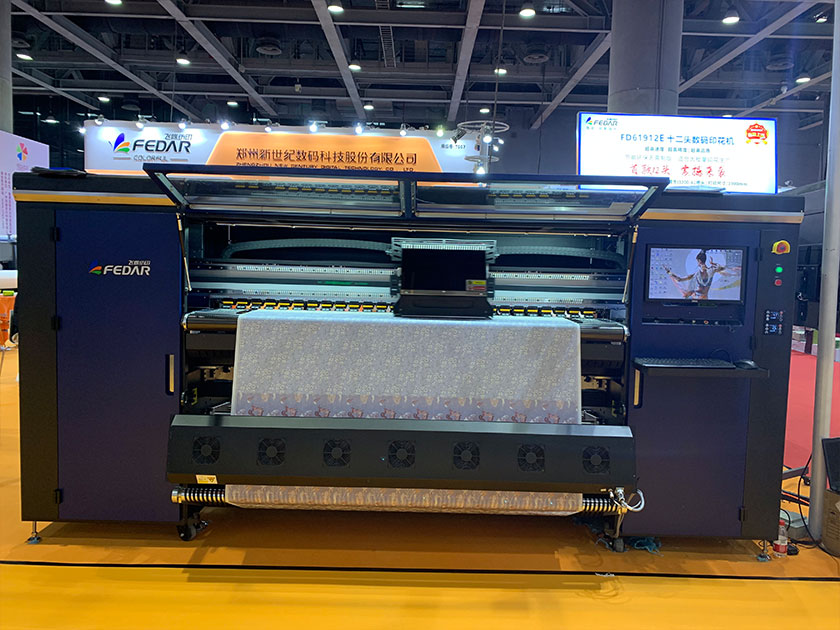

-Fader

-Audley

-Grando

-Hopetech

Etc.

Kyocera Dye Sublimation Printer For Fabric Printing:

-Atexco

-Homer

Etc.

In short, in solvent printers, mainly Konica 512i/ 1024i, Starfire 1024 25PL, and Seiko 1024 HG.

In Eco solvent printers, all printers are equipped with Epson i3200, and some factories are promoting EPSON i3200 S1HD, and 8 colors or 6 colors eco solvent printer.

In UV field, mainly Ricoh G5/6, Konica 1024i/1024A, Epson T3200 U3/i3200 U1 and Kyocela.

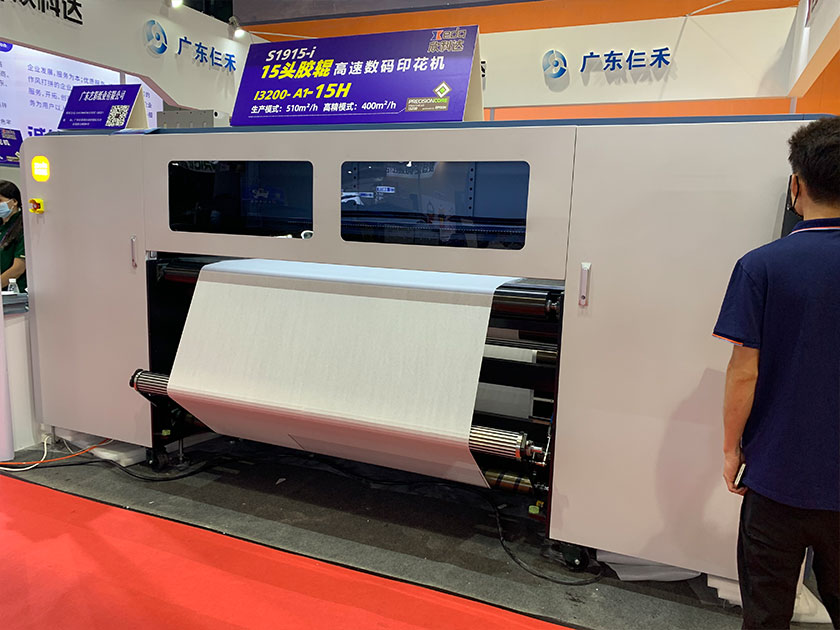

In the sublimation printers, mainly Epson i3200 (8-16 heads), Epson S3200 and Kyocera.

In the DTF pigment printers, mainly Epson i3200/ 4720 (2- 4 heads), Like Fader, Xenons, Audly, Jade etc.

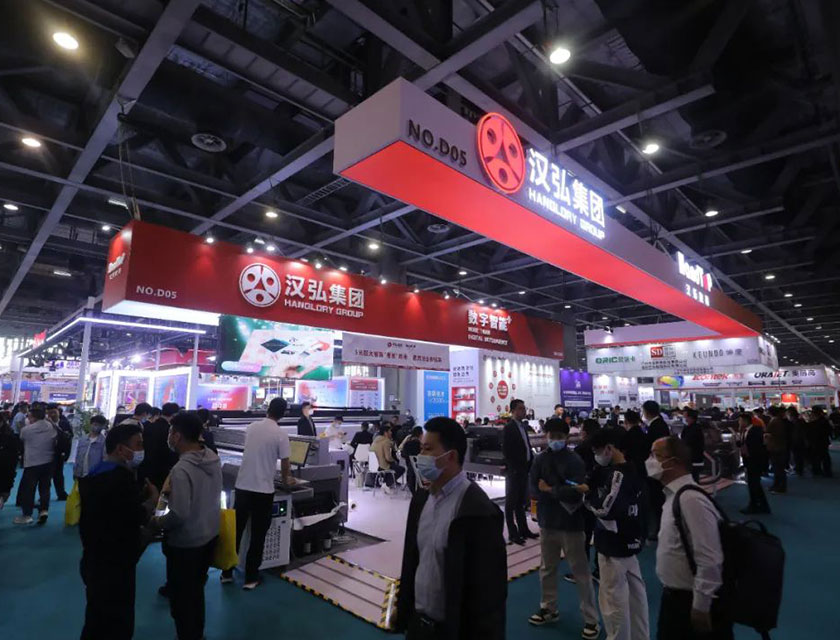

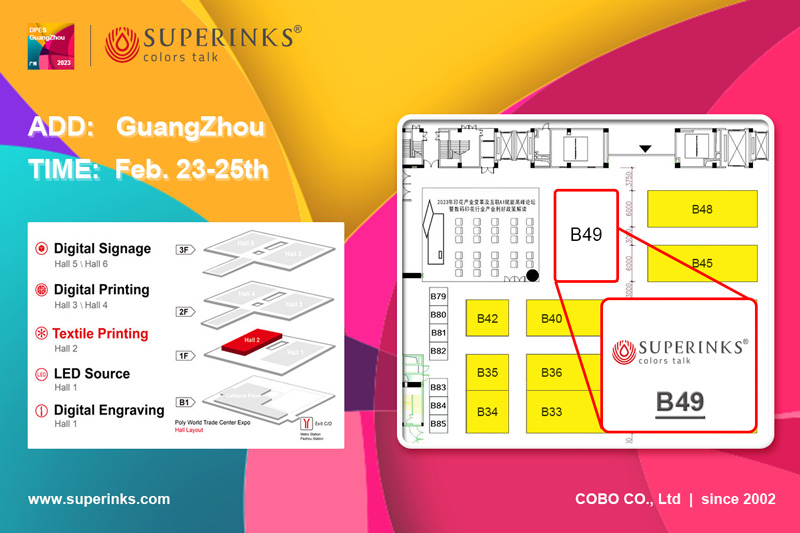

On February 23-25, 2023, we participated in the DPES exhibition held in Guangzhou Pazhou Poly World Trade Expo Hall.

At the exhibition, SUPERINKS met with a number of customers who have already made deals and also received many customers from Vietnam, Thailand, Malaysia, Turkey, Mexico and other countries. Our ink has also received praise and support from customers.

SUPERINKS is not just an ink supplier, we can help customers make more correct choices, reduce the cost of mistakes, and create more value for customers.

DPES exhibition location of SuperInks: H2 B49.

Youtube: https://youtu.be/LAs9uRoyfFU.

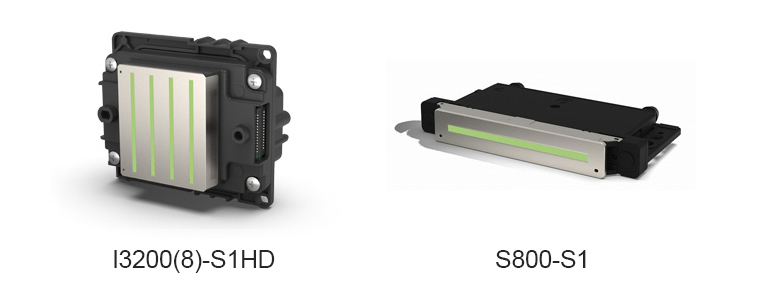

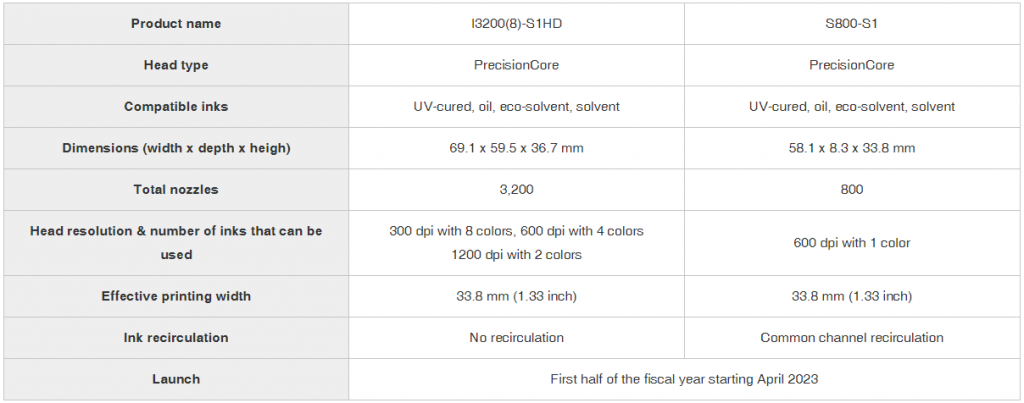

Starting from April 2023, EPSON release new printheads that support solvent inks: the new I3200(8)-S1HD and S800-S1, two printheads that are used in industrial Compatible with various inks applied. In addition to UV-curable, eco-solvent, and water-based inks, they also support solvent, oil-based and other types of inks for digital printing applications in production printing.

【EPSON I3200(8)-S1HD】Solvent Compatible = Suitable for various printing requirements such as displays and solar cells by using suitable solvents with high solubility. Easy to install up to 8-color printing, high-quality printing = Up to 8 different ink colors can be used, not only CMYK color inks can be ejected, but also different types of liquids can be ejected, which can flexibly respond to industrial printing applications. In addition, while realizing high-definition image quality of 1200dpi, it is not only suitable for multi-path printing, but also suitable for single-path high-speed printing.

【EPSON S800-S1】Small design=For ink suitability, it has the same performance as “I3200(8)-S1HD”, however, it is also possible to print on substrates close to the 3D surface in a limited space by using only one chip design.

You can check this DPES 2023 exhibition URL for more information: https://www.chinasignexpo.com/Itex/en/.

Address: Poly World Trade Center Expo, Pazhou, No.1000, Xingangdonglu, Haizhu District, Guangzhou, China

Exhibition Tel: +86 20 8908 9736

Welcome to visit the SUPERINKS booth at Hall 2, B49.

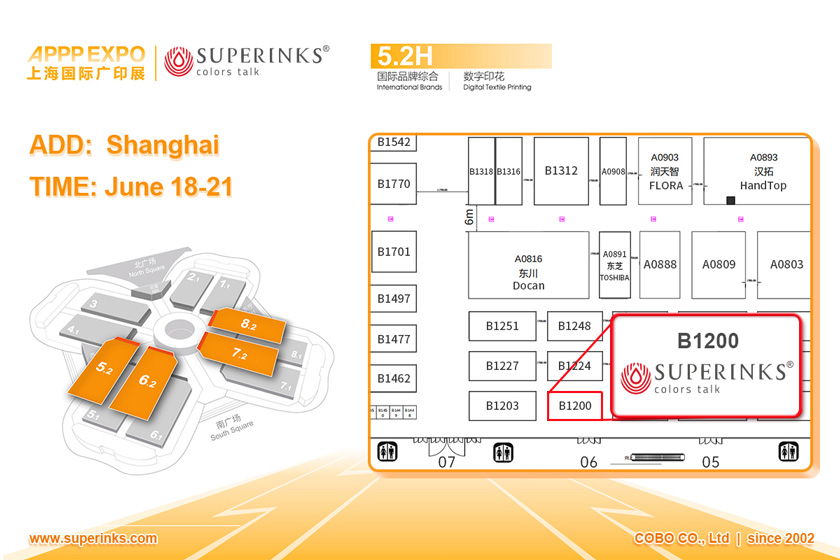

You can check this exhibition URL for more information: http://www.apppexpo.com/lang/en.

Address: National Exhibition and Convention Center (Shanghai) No.333 Songze Avenue, Qingpu District, Shanghai, China.

Exhibition Tel: 86-21-34080380

We all know that for years, APPPEXPO has always been held in March.

In the year 2021, it changed to Sep because of COVID-19.

In the year 2022, it will not be held because of COVID-19.

Now in the year 2023, it will be held in June.

In Dec. 2022, when APPPEXPO decides the exhibition time, they think probably in March 2023, the Chinese Covid policy about foreigner visits to China not open yet (the Chinese stopped Covid isolation in Dec. 2022), and probably the peak of Chinese people’s infection with the covid has not passed yet. So they changed the time from March to June in the middle of Dec. 2022.

Welcome to visit the SUPERINKS booth at Hall 5.2, B1200.

DTG ink, also named direct to garment ink, which is a kind of water-based pigment ink for the digital textile printers, and direct print on finished T-shirts. As long as the finished T-shirts printing area is small, the DTG printers are usually small size, A3 or A4 flatbed, with Epson i3200-a1 or 4720 or DX5 heads.

Mostly, DTG inks are works on cotton textiles. When it prints on light/white/blank cloth, the printer only use KCMY, etc. colors. If it prints on dark/black color cloth, we have to print a layer of white first, and then print color picture, the printer will includes a white color.

With the development of technology, the DTG ink will prints on other textile types, like polyester, or polyester and cotton mix fabric. And it will goes to a rolling machine, for industrial-scale printing, pre-coating the fabric by an industrial-scale factory.

There is pre-coating liquid in 1:10, and in 1:20, or other customized proportions.

And the clean liquid is available.

More than 10 years ago, there was Epson water-based print head DTG printers, the suppliers modified for Epson desktop printers like R1390, T50, T60 4880 9880 etc. They just do small modifications, and suppliers’ technology is weak, the printing is not stable, and the printers’ performance experience is very bad.

In the second stage, in about the year 2010, while Chinese printer companies on the ability to make good quality printers. There are totally new made DTG printers, with stable quality. But the color resistance of DTG ink is weak, at about 3-4 levels. To strengthen the color resistance, they add complicated pre-coating and after the coating processes. While the non-programmed manual operation coating process, the quality of color resistance is still not stable.

In the third stage, after the year 2020, after the DTF boomed up. There is one raw material, which works both on DTF ink and DTG ink and brings better adhesion for DTG ink. In light / white / blank cotton garments, DTG ink delivers a softer texture than DTF. Then DTG works on high-level products, DTF goes on lower.

To do DTG printing, you need other related products except for DTG inks as:

DTG ink is a kind of water-based pigment ink, environmentally friendly and harmless to the body.

In the year 2022, DTG ink suppliers in the Chinese market, for wholesale quantity more than 1000 KGS, DTG color inks (CMYK LC LM, etc.) price about ¥180-250 / KG, white ink in ¥250-¥400 / KG. The price ranges according to time and technology updates.

DTG ink is not sublimation ink.

Mostly, sublimation ink is water-based dye heat transfer sublimation ink, it prints on a kind of coated heat transfer paper, and then transfers to polyester textiles. And there is a kind of direct print on coated polyester sublimation ink too.

DTG ink works on cotton, and direct print on the cotton garment, with no need for transfer.

In the garment market, we use color resistance levels to measure it. DTG prints’ color resistance level is usually between 4-5 levels. Compare to 5-level sublimation, DTG’s color resistance level is lower.

For sublimation printing, as our information from the market, Epson i3200-a1, 2-3-4-6 heads sublimation printers are old model to market, and 8 heads ones are hot selling in the year 2021. Then how about more heads?

Report time: Aug 22, 2022

Author: Mrs. Kyna Zhou

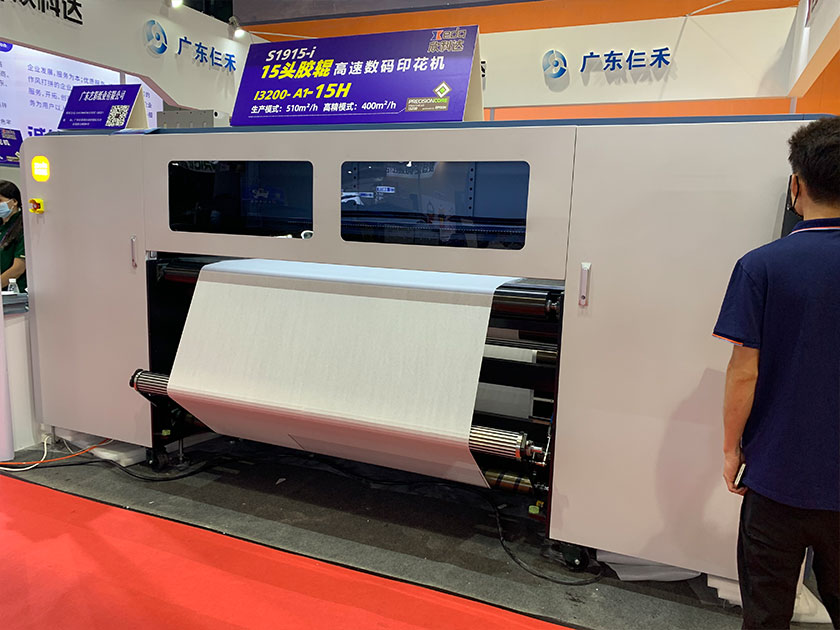

ITCPE 2022 (17th) Guangzhou International Textile Clothing and Printing Industry Expo

Time: Aug 18-20, 2022

Address: Poly World Trade Center Exhibition Hall, Guangzhou, China.

Which printer brands are promoting more than 10 heads i3200-a1 sublimation printers?

All the above brands showed 8 heads printers as a basic printer.

Which printer brands are promoting S3200 sublimation printers?

Which brand printers?

Infinity Kyocera 8 heads reactive printer.

DTG to garment T-shirt, not only small A4 printer with 1 or 2 or 3 flatbeds, but also big ones combine with silk screen elliptical machine. There is supplier said, he research out a kind of paste, it is more environmentally friendly, better color fastness, will not penetrate the other side of the ink.

Digital DTG printer brands as:

“Printpretty” said they can print on wet textile (Which we said Kornit can, but other Chinese printers can’t). It uses Starfire 1024 heads. We need to see whether it will be or not.

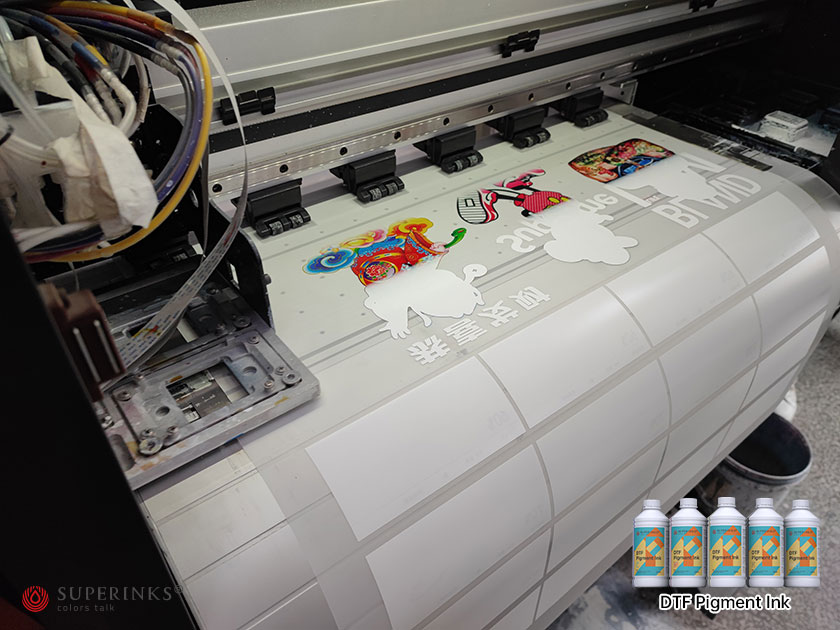

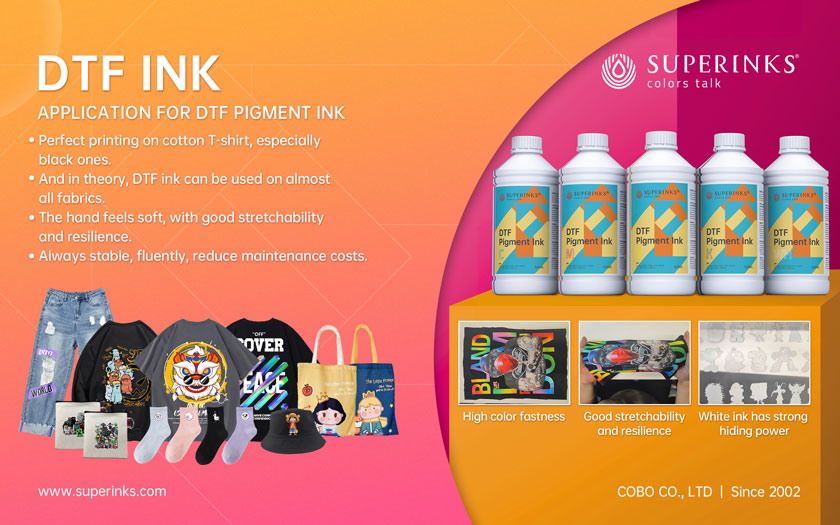

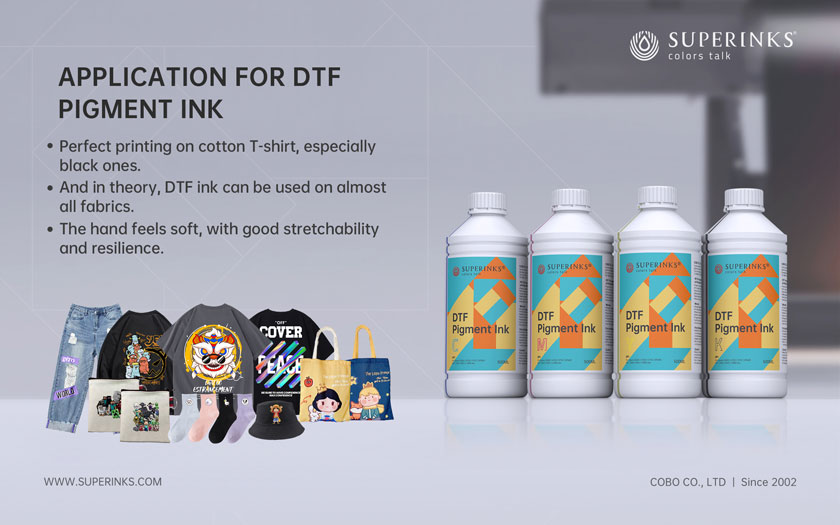

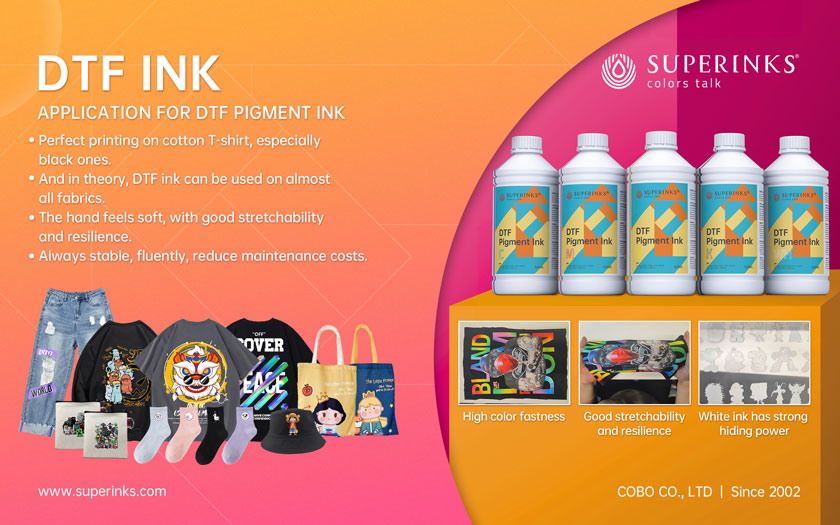

Check out the video of using DTF ink to give you a preliminary understanding of it.

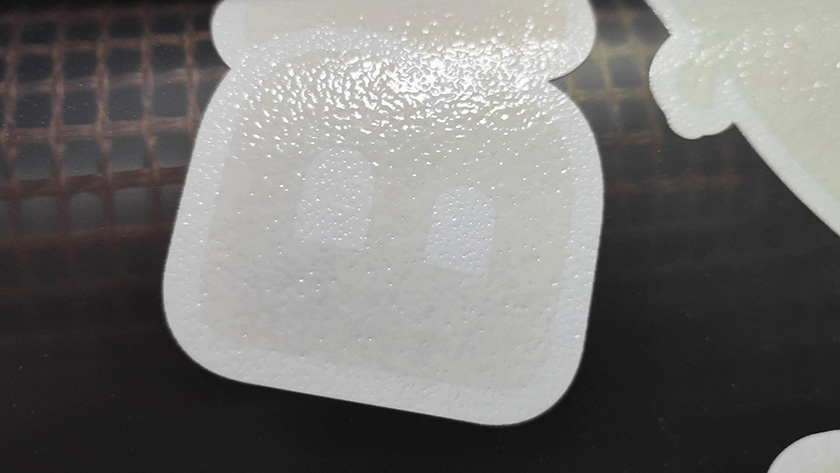

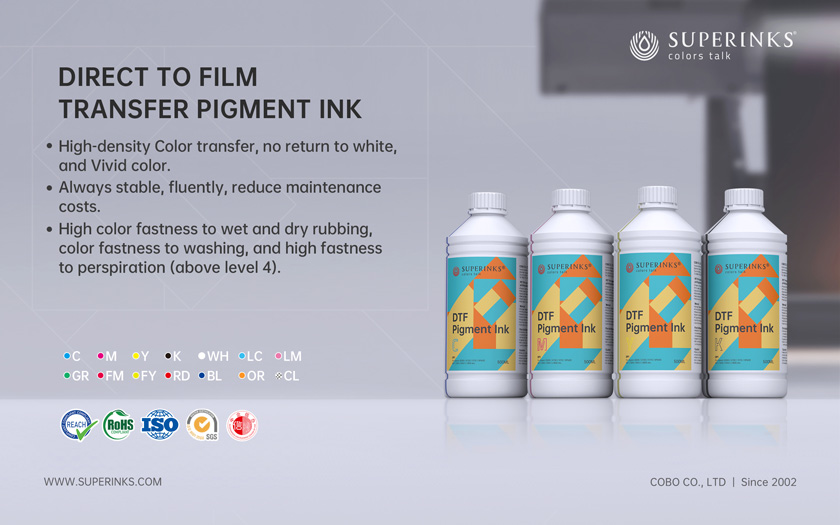

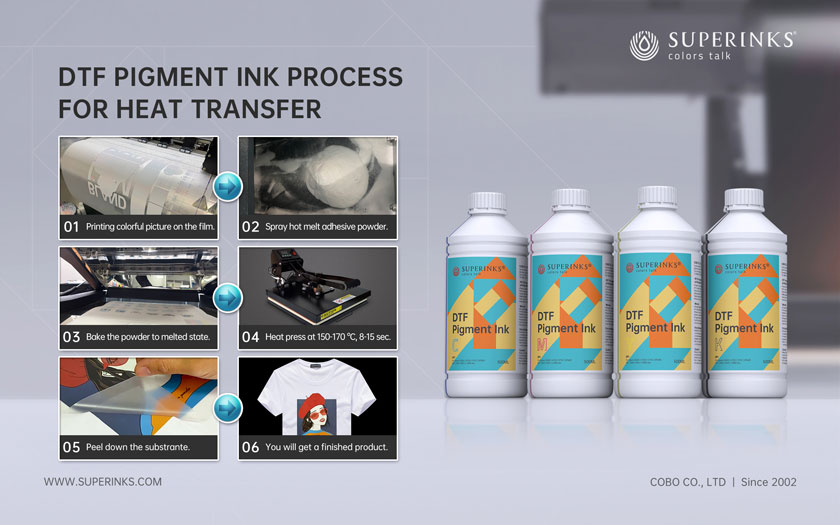

There is a layer of coating on the surface of the film. The function of the coating is to absorb ink and hold the ink, making the picture sharp. Meanwhile, the coating is a kind of flexible layer, when you stretch it, it will not break.

Because of the working step 1‘s film, in the working step 2, you can get a sharp picture. meanwhile, the white colour ink will be covered the surface of the colourful picture. White colour is very important in this technology. It will be the background of the picture on the black/dark T-shirts, to make the colours shinny. White ink also is flexible to bear stretch. And the “wet/not dry” white ink has the function of loading “hot melt powder” in the next step.

Hot melt powder is the biggest new part of this technology. Previously, we use hot melt powder in the silk screen’s white. The function of hot melt powder is “glue”, sticking the layer of the picture to the textile. When you heat this kind of powder, it will turn to liquid, and turn sticky. But in a normal environment temperature, it is a solid powder.

So, after step 4, you get a beautiful picture, with a layer of white background, and then a layer of “glue” background. And more importantly, the “glue” is not sticky at a normal environment temperature. You can roll it up to send to customers, to store there.

In step 5, you can cut down the film, without caring about the shape of the picture edge, put it on the surface of cotton textile, press and heat. And then you can peel down the layer of film (without coating), and leave the picture on the textile.

DTF ink is for cotton T-shirts, with flexible pictures, can do big-scale industrial use.

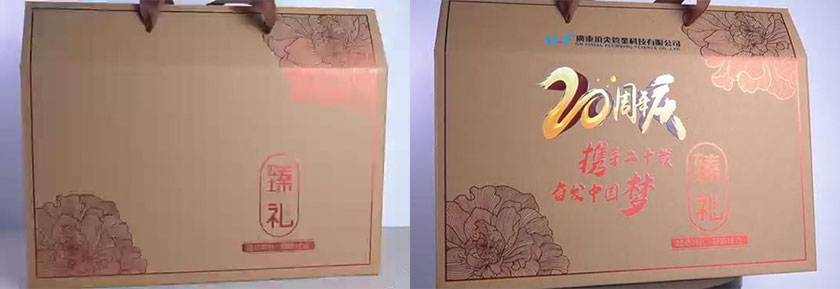

DTF UV printing is for hard substrates, like gift pictures.

There are 2 methods For DTF UV ink printing.

This glue direct printing DTF UV can do industrial printing, and the printer is very cheap. We can have good wishes for this. But the glue printing by head is still a big challenge and difficult to improve.

DTF UV printing only works on hard product surfaces. It is for small logo printing. Does not require any plate making, can do small quantity printing. Very fast printing, customer send job, wait half hour, then he can take the finished product away. This kind of printing job with very high-profit margin.

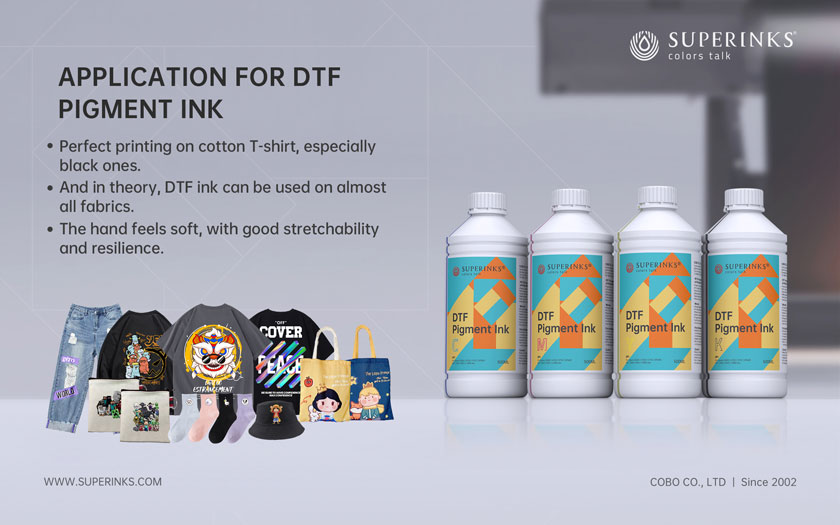

DTF (direct to film) printing ink is a kind of special pigment ink. If you use normal pigment ink on DTF printing, it will not work well. This kind of DTF ink has very good adhesion with cotton textile, and it has special components to make good flexibility.

DTF ink has very wide compatibility with different textile types. It has a very big market in the clothes market.

DTF textile pigment ink works on textile, especially on a cotton T-shirt, which is upgraded from silkscreen and DTG ink. Bright, high wash resistance, soft.

There is a shortage of silkscreen printing: need to make the plate, labor cost high, speed slow, not precision, cost per color, not colorful, pollute.

DTG (Direct to garment) ink is digital printing, no need to make the plate, less labor, less time cost, very precision, and more colors do not increase the cost. But the shortage is: not bright enough, wash resistance is weak.

DTG pigment ink printing for T-shirts is an old technology but had not had a big market share for years. DTF technology almost solved all problems that DTG has. It solved not bright enough color, not good wash resistance.

Though the hand feel of DTF is a little bit more, it will go better if choose the best ink and hot melt powder, and it can be improved step by step.

T-shirt printing is a huge market, especially pure cotton, especially black pure cotton T-shirts (Before, no technology solved well how to print a soft and bright pure cotton black T-shirt).

DTF (Direct to film) ink is improved from DTG ink, it has all advantages of DTG ink, and improved its shortage. DTF ink is very bright and has high wash resistance and high scratch resistance. Only you need to choose a good quality hot melt powder and make film and powder and ink perfect matches.

SUPERINKS works out a whole solution for DTF ink and offers to match hot melt powder and PET film.

https://www.facebook.com/100003778275523/videos/2065692960233293/

The following print heads can use SUPERINKS DTF printer ink.

Grando, Oric, keundo, Taimes, Xkeda, Skycolor, Fedar, Allwin, GZ, Wit-color, Titanjet, Bonssrom, etc.

DTF printer ink (direct to film) is a kind of special pigment ink designed for cotton fabrics and can expand to many different substrates.

It has been a new technology since March 2020 and spread promptly. It perfectly replaced a big part of DTG T-shirt printing.

DTF’s working principle is: print on a film with coating on its surface, the coating carried ink well. Firstly print the colorful picture with CMYK and other colors, and then print a layer of white ink. Then it is shipped to a machine, which can spread “hot melt powder” on the wet surface of the printed picture, and then bake it to dry. Then you can roll it up to send to another workshop, or you can cut one piece of the picture, and then heat and press the picture, it will transfer from film to a fabric.

No, DTF ink is not same as DTG ink.

Though both inks are pigment inks, they are different types of pigment ink. DTF’s processes are different from DTG, and the working principles are different too. The final effect is different either: DTF printing T-shirt is more bright, better color resistance. DTG printing T-shirt has a softer hand feeling.

Kyocera KJ4A

Black, Cyan, Magenta, Yellow, Light Cyan, Light Magenta, Gloss, White.

Print on canvas for outdoor banners for roadside advertising, shop sign, shop promotion, etc.

PVC flex, car sticker, wallpaper, oil painting canvas, glass-ceramic, acrylic, metal, wood, rigid PVC, etc.

Print on canvas for outdoor banners for roadside advertising, shop sign, shop promotion etc.

PVC flex, car sticker, wallpaper, oil painting canvas, glass-ceramic, acrylic, metal, wood, rigid PVC, etc.

Print on canvas for outdoor banners for roadside advertising, shop sign, shop promotion etc.

We have two options for customers:

Low odor

Print on canvas for outdoor banners for roadside advertising, shop sign, shop promotion, etc.

We have two options for customers:

Self-adhesive vinyl, PP adhesive, PVC flex banner, Backlit PET Film, photo paper, one-way vision, canvas, etc.

Gongzheng, Witcolor, Flora, etc.

FY-Union, Phaeton, Galaxy, Challenger, Infinity, Ico-tec, etc.

There is two option for the customer.

Black, Cyan, Magenta, Yellow,

light cyan, light magenta,

Clean liquid.

odorless.

Print on canvas for outdoor banners for roadside advertising, shop sign, shop promotion, etc.

Allwin, Grando, Eric, Keundo, GZ, Wit-color, JHF, Liyu, Flora, Handtop, Pheaton, Crystal, UD-printer, FY-union, Galaxy, EFI, Times, Xenon, Human, etc.

There are two outdoor durability options for customers.

Self-adhesive vinyl, PP adhesive, PVC flex banner, Backlit PET Film, photo paper, one-way vision, canvas, etc.

Self-adhesive vinyl, PP adhesive, PVC flex banner, Backlit PET Film, photo paper, one-way vision, canvas etc.

Skycolor, Xkeda, Grando, Eric, Keundo, Allwin, GZ, Gongzheng, Wit-color, Flora, Handtop, etc.

From the market response, it is 8-10 months time.

Car sticker, PP adhesion, backlit banner, front-lit banner, backlit film, photo paper, one-way vision, painting canvas.

corrugated poster, cardboard, etc.

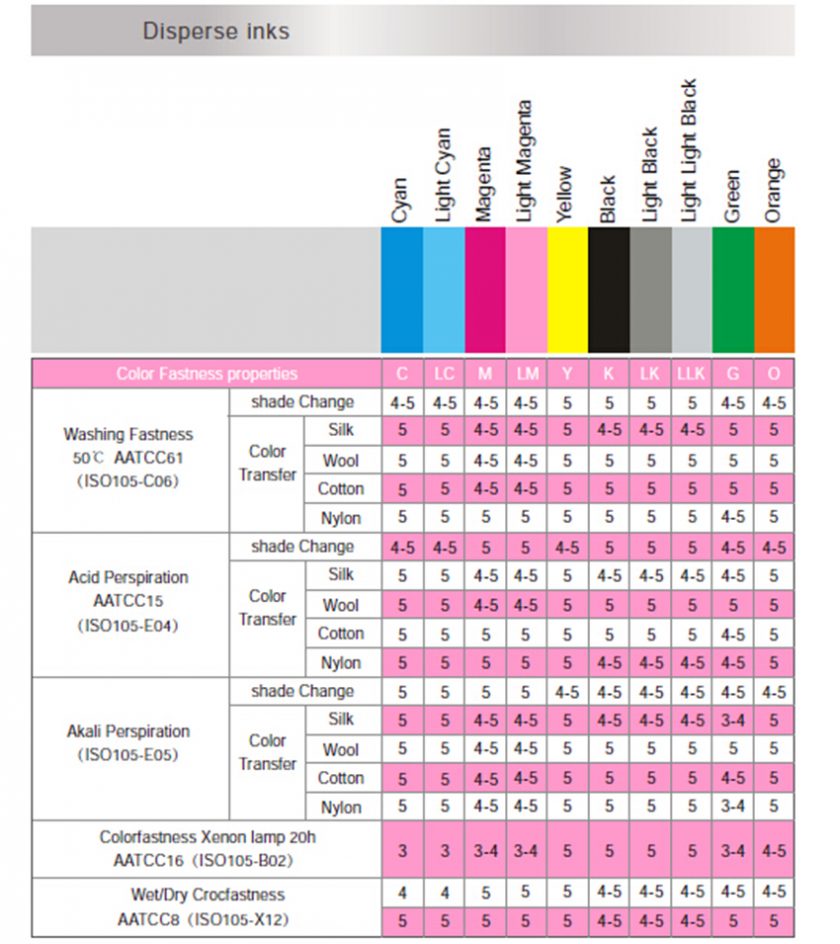

Actually, from the ink technology, it is the same ink. But the working process of using is different. Sublimation ink mainly uses two methods, one is printing on heat transfer paper, then heat transfer to polyester, normally for clothes. Another is direct printing on sized polyester, normally for AD flags. Both without water wash, mean with less pollution. Disperse ink, usually working as the following process. Sizing, dry, printing, steam, wash, dry.

All those 3 inks are mainly for cotton fabric. Each ink has a different process. Disperse ink can get the best color, and best resistance, but need a more complex process. More used for high-quality level printing.

DTG pigment ink printing for T-shirts is an old technology but has not had a big market share for years. DTF technology almost solved all problems that DTG has. It solved not a bright color, not good wash resistance. Though the hand feel of DTF is a little bit more, it can improve step by step.

T-shirt printing is a huge market, especially pure cotton, especially black pure cotton T-shirts (Before, no technology solved well how to print a soft and bright pure cotton black T-shirt).

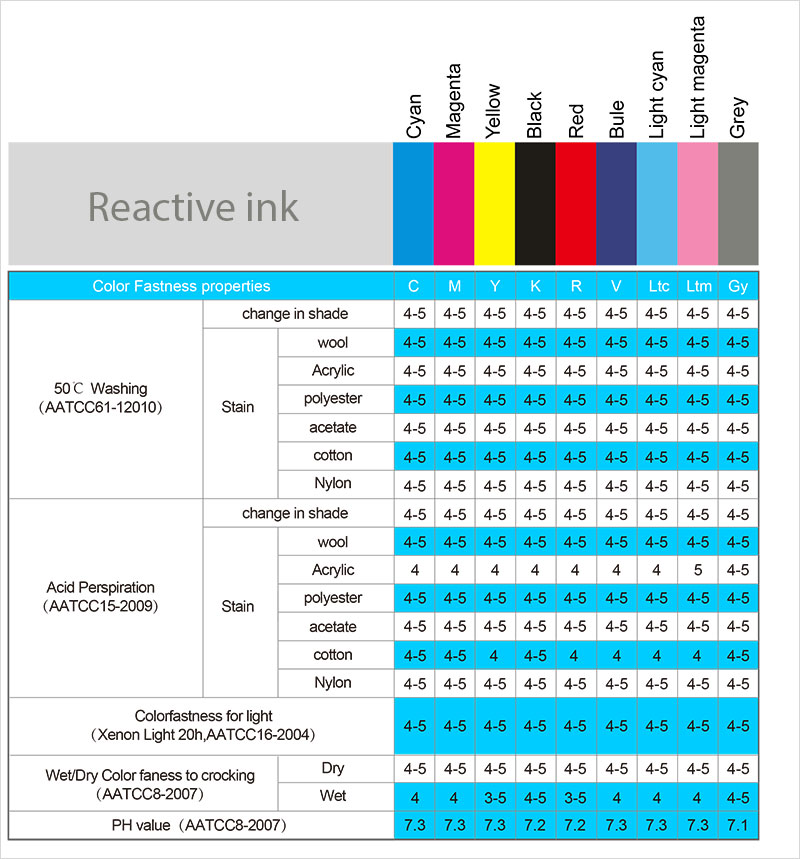

All those 3 inks are mainly for cotton fabric. Each ink has a different process. Reactive ink can get the best color, and best resistance, but need a more complex process. More used for high-quality level printing.

DTG pigment ink printing for T-shirts is an old technology but has not had a big market share for years. DTF technology almost solved all problems that DTG has. It solved not a bright color, not good wash resistance. Though the hand feel of DTF is a little bit more, it can improve step by step.

T-shirt printing is a huge market, especially pure cotton, especially black pure cotton T-shirts (Before, no technology solved well how to print a soft and bright pure cotton black T-shirt).

Black, Cyan, Magenta, Yellow, Light Cyan, Light Magenta,

Clean liquid.

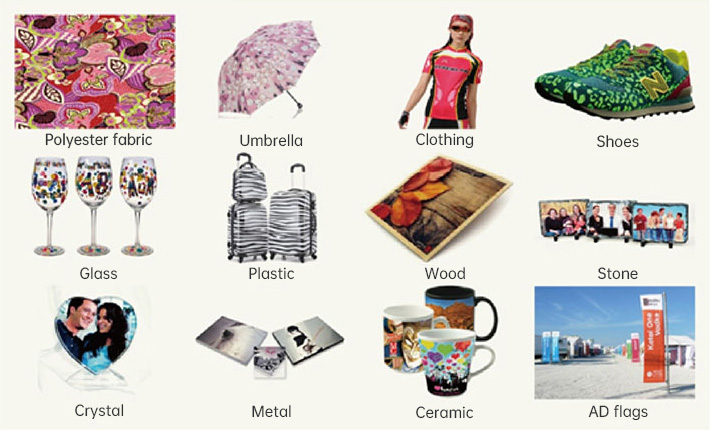

Textile as: polyester cloth, nylon cloth;

Hard media like glass, crystal, ceramic, metal, wood, etc.

Fabric printing (clothing, shoes, hats, curtains, ties, bags, umbrellas, clothing accessories, webbing), making personalized cups, cutlery, kettles, pen cases, personalized photo albums, etc.

You need special ink for sublimation. Not all sublimation ink is the same, there is a different density for different types of sublimation ink, and in different models, different suppliers’ ink has different color tones and different stability. You can not use any kind of sublimation ink, you have to use match ink. Tell the supplier what printer and head you use, what process of printing you do, what kind of fabric you do, and what application, and then you can get a matching ink. Epson is compatible with sublimation ink. Also Roland and Mimaki.

HP stitch s500 is sublimation ink printing too, but its head uses heat bubble technology, which different system from Japanese printers and Chinese printers.

Can you switch from regular ink to sublimation ink?

Sublimation ink is a kind of water-based safe ink that only shows its beautiful color after heat, before heat the color of the ink is dark and old. This kind of ink will have a chemical reaction while heating from paper to fabric, after the chemical reaction, the color gets bright and firmly fixed on the fabric without hand feel. Normal ink doesn’t meet that chemical reaction.

You can switch a printer from regular ink to sublimation ink, as long as totally cleans the regular ink, and the printer and printhead match the sublimation ink needs.

Sublimation ink is a kind of special inkjet ink, it is different from office use desktop water-based dye ink.

For Epson i3200-a1, 4720, 5113, DX7, DX6, DX5, DX4, xp600, TX800, etc. print heads.

Atexco, Hanglory, Homer, Efi, Liyu, JHF, Flora, etc.

Skycolor, Fedar, Xkeda, Grando, Eric, Keundo, Human, etc.

Fabric printing (clothing, shoes, hats, curtains, ties, bags, umbrellas, clothing accessories, webbing), making personalized cups, cutlery, kettles, pen cases, personalized photo albums, etc.

Temperature: 20-30℃. If beyond the temperature range, please use a heater or air conditioner.

Humidity: 40-60%.

DTG ink printing for T-shirts is an old technology but had not had a big market share for years. DTF technology almost solved all problems that DTG has. It solved not bright enough color, not good wash resistance. Though the hand feel of DTF is a little bit more, it can be improved step by step. T-shirt printing is a huge market, especially pure cotton, especially black pure cotton T-shirts (Before, no technology solved well how to print a soft and bright pure cotton black T-shirt).

We have DTG ink too, you can inquiry us if you are interested.

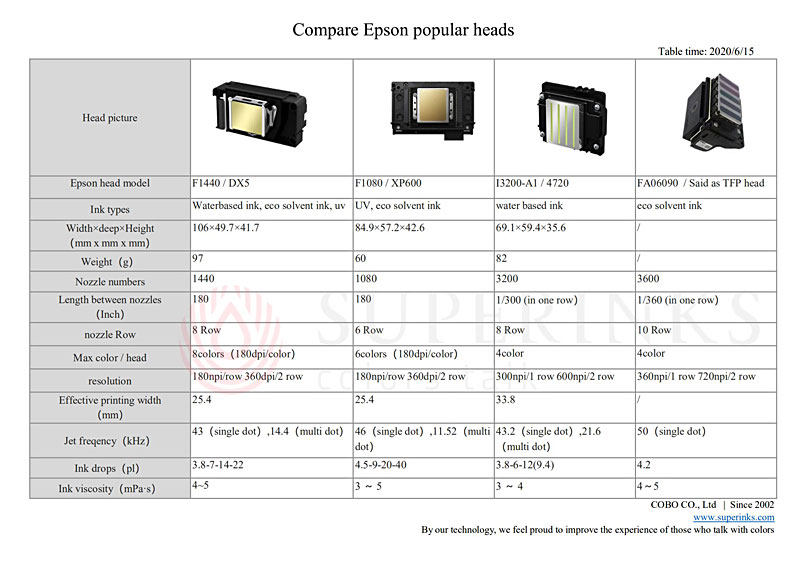

As we all know, Epson heads as a popular head brand in the inkjet digital printing area, with its unique micro piezo printing technology, leading the area. The microprinting technology with the advantage of high printing solution, good durability, environmental, efficient-cost, etc, with this advantage, Epson can design heads with high-quality printing and high production printing. Now, let’s talk about some Epson popular heads.

This is a classic good print head, with a price of USD 860-1000 per piece, head life is about 2-3 years. And this is a head with a long history, which release in about the year 2000 also.

EPSON F1440 (DX5) is the most popular head in the Epson brand, it can perfectly use ink types such as water-based dye ink, sublimation ink, eco-solvent ink, and UV ink. And the market support system for the heads is perfect and mature. Almost all printer brands have their printer model with Epson DX5 heads.

It is an economical head designed as a water-based head, head life is about 6-18 months, with a price of USD 150- 250 per piece. Printer brands like it because they plan to make a simple printer and sell it in big quantities.

XP600 which was released in about the year 2018, is a head with 6 channels, the color saturation of xp600 will be worse than DX5 and i3200. But with its very cheap price and moderate stability, it is widely accepted by the market. It is mostly used on small level eco-solvent ink printers, roll UV printers with 1.6-1.8 width, and flatbed UV printers with 6040 or 9060 sizes.

Epson i3200 is designed as a water-based head, which was released in about the year 2018 also, the price ranges from USD 240- 300. Same as XP600, printer brands like it while they plan to make a simple printer and sell in big quantity.

I3200 head uses thin-film piezoelectric (TFP) technology, head life may be similar to the DX5 head. The advantage of i3200 is: that with more nozzles 3200, higher resolution 600 DPI, and jet frequency, which are all higher than DX5 and xp600, then it acts better in color saturation, printing speed, and printing precision, and the price is cheap. It is popular in sublimation ink textile printing.

Epson TFP head release in about the year 2016, use thin-film piezoelectric (TFP) technology, the price at USD 1800-2000. This head is only used on Epson brand wide-format printers, such as Epson SureColor S 30680 /40680 /60680 /80680, etc.

Epson TFP head with Epson company’s high standard output, it acts brilliant at printing precision, color expression, color saturation, it’s much better than above listed heads. The customer with the high standard requirements will choose this head.

Article time: Mar 2021

2021 APPPEXPO exhibition location of SuperInks: 3H A0654.

Youtube: https://youtu.be/IID1YhebW4c.

Superinks nice exhibition in Indonesia Jakarta Jiexpo 2019 ALL PRINT.

2019 APPPEXPO exhibition location of SUPERINKS: A0020.

Youtube: https://www.youtube.com/watch?v=zWBSphi5KWc