Beware of Low-Price Traps in Digital Inkjet Inks: Exposing the “Low-Cost Gimmicks” Across Five Key Categories

When browsing the wide range of digital inkjet inks on the market, “low price” often stands out as the most tempting selling point. Yet behind this seemingly budget-friendly label, unscrupulous suppliers frequently hide cost-cutting tricks that end up costing you more in the long run—not only driving up ongoing expenses but also risking equipment damage, poor print quality, and even costly after-sales disputes. Today, we’ll break down the truth behind low-priced inks for five major inkjet categories, helping you steer clear of purchasing pitfalls.

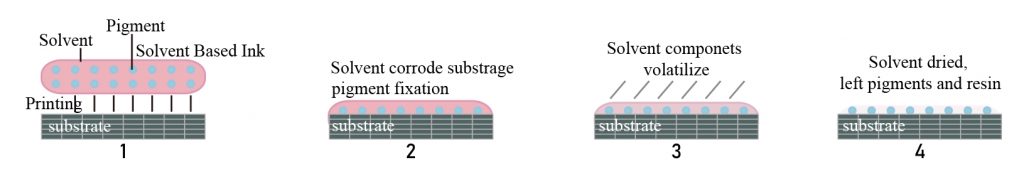

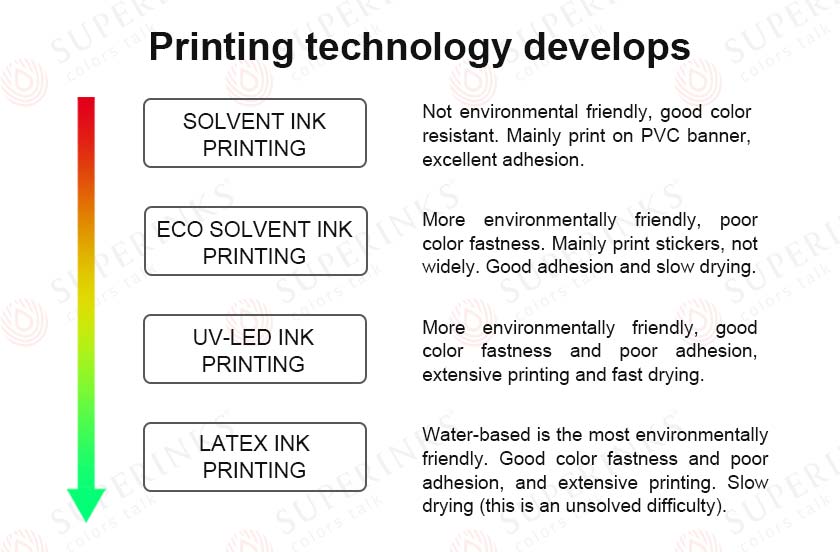

1. Solvent-Based Inks: Cutting Corners Equals “Double Loss”—Hidden Waste Lurks in Low Prices

Solvent-based inks are commonly used for outdoor advertising, industrial signage, and similar applications, where basic adhesion and weather resistance are non-negotiable. Unscrupulous suppliers’ low-price tactics boil down to “subpar materials and shorted quantities,” tricking buyers into thinking they’re saving money while sacrificing quality and value:

- “Downgraded” Raw Materials Spike Maintenance Costs: Instead of using compliant imported colorants and specialized solvents, these suppliers opt for low-purity, inferior alternatives. The result? Pungent odors and frequent nozzle clogs. What used to be routine maintenance (once or twice a month) can turn into weekly nozzle teardowns and cleanings—wasting labor and accelerating nozzle wear.

- Thinned Ink Density Boosts Consumable Waste: To cut costs, ink concentration is heavily diluted, drastically reducing color strength. Achieving the desired hue now requires slower print speeds, more PASS cycles (repeated printing), and higher ink output. While a 1L bottle may seem cheap upfront, it delivers 30–50% less usable print volume than high-quality ink—driving up total costs.

- Shorted Packaging: The “Hidden Shortage” Gimmick: Labels lie about volume: a “1L” bottle might only hold 800–900ml, and a “5L” container could be short by 200–300ml. Branded as “low-price, large-capacity,” these products are really just “low-priced but underfilled”—you end up paying for ink you never receive.

2. Eco-Solvent Inks: Harmful Additives Risk Safety and Equipment Lifespan

Eco-solvent inks (often called “environmentally friendly solvent inks”) are popular for indoor wide-format printing, decorative art, and display stands, thanks to their low odor and broad compatibility. But low-priced options cut corners by “compromising safety and overpromising performance,” creating hidden risks:

- Overused Harmful Components Endanger Health and Gear: To save money, suppliers use ethylene glycol butyl ether acetate—a solvent-based ink ingredient, not a standard eco-solvent component—as the main base. This creates two major issues: first, the strong odor irritates airways in enclosed spaces; second, it corrodes the rubber gaskets and metal parts inside nozzles. A nozzle that should last 1–2 years might leak or clog in just 6 months—and replacing it costs 10–20 times more than the cheap ink itself.

- Faked Durability: Rework Costs Outweigh Savings: Inks that only last 8–10 months outdoors (against sun and rain) are falsely marketed as “fade-resistant for 2 years.” Print outdoor banners or store signs with this ink, and you’ll soon see yellowing or peeling. The cost of reprinting—materials, labor, and downtime—far exceeds what you saved on the ink.

3. Sublimation Inks: Shoddy Colorants Ruin Product Reputation Overnight

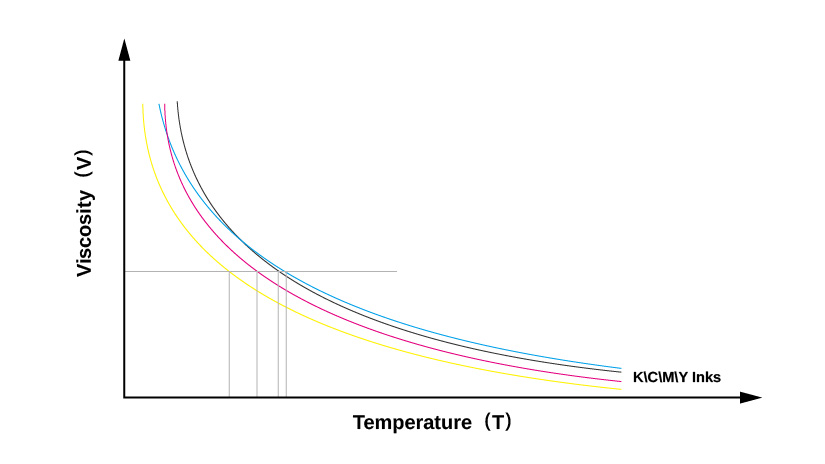

Sublimation inks are designed for textile printing (T-shirts, scarves) and personalized gifts (mugs, pillows), where “color fastness” and “wash resistance” are make-or-break. Low-priced options undermine these core qualities, leading to costly quality failures:

- No-Cost-Spared Density Cuts: Dull, Uncompetitive Colors: By reducing colorant levels, suppliers lower costs—but prints end up dull, low-saturation, and even “see-through.” On dark fabrics, the base color shows through, making products look unprofessional and unmarketable.

- Cheap Colorants Spark After-Sales Headaches: Instead of using specialized sublimation colorants, suppliers use low-adhesion alternatives. The result? Textiles fade or bleed after 1–2 washes, and mug designs peel off when heated. This doesn’t just disappoint customers—it leads to returns, complaints, and permanent damage to your brand’s reputation.

4. UV-Curable Inks: “Eco-Friendly” Becomes Harmful—Weather Resistance Disappears

UV-curable inks are a top choice for hard surfaces (wood, glass, metal) because they dry instantly and emit minimal fumes (a key eco-friendly benefit). But low-priced UV inks use “component fraud” to cut costs, erasing their advantages and ruining performance:

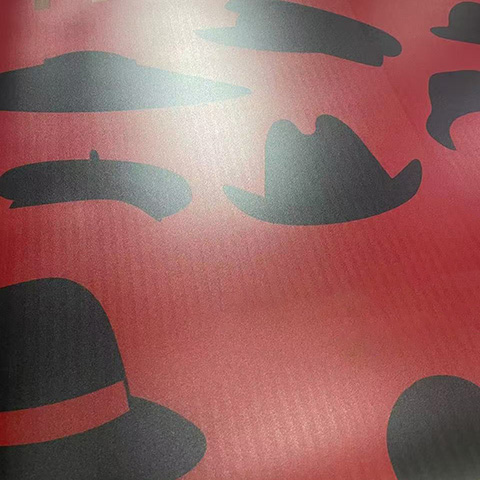

- Inferior Monomers + Extra Solvents: Multiple Risks in One: Quality UV inks rely on high-purity photo-curable monomers. Cheap versions use low-grade domestic monomers and add extra solvents (to thin the ink and save money). This causes three problems: ① Strong fumes destroy the “eco-friendly” label, making them unsafe for enclosed spaces; ② Solvents corrode precision nozzle parts, shortening their life; ③ Poor curing leads to soft prints that scratch easily.

- Weakened Weather Resistance: Outdoor Prints Fail Fast: Inferior monomers and excess solvents destroy the ink’s UV resistance and anti-aging properties. Outdoor signs or glass curtain wall prints may yellow, crack, or peel in just 3–6 months—completely contradicting UV ink’s “long-lasting outdoor performance” promise.

5. DTF Inks: Core Performance Collapses—Printing Becomes Unreliable

DTF (Direct-to-Film) inks are a recent favorite for textile printing, requiring three key traits: “coverage” (hiding dark fabrics), “stretchability” (adapting to fabric movement), and “stability” (no nozzle clogs). Low-priced DTF inks break all three rules, making printing nearly impossible:

- Shoddy Resins: Zero Transfer Durability: DTF’s bond to fabric depends on high-adhesion specialty resins. Cheap inks use low-stick alternatives—prints peel off with a light rub, rendering finished products useless.

- Over-Diluted Density: Bad Coverage + Clogged Nozzles: Repeated dilution cuts costs but leaves ink too thin to cover dark fabrics (the base color shows through). Worse, thin ink clogs nozzles constantly—cleaning takes hours, and severe clogs can ruin nozzles entirely.

- Unstable Formulas: High Scrap Rates: Unbalanced ingredient ratios cause ink to separate or settle. Printing becomes a nightmare of skipped lines and uneven color—wasting transfer film, fabric, and ink. The cost of scrap alone is far more than the “savings” from cheap ink.

In China’s competitive ink market, production costs and profit margins for quality products are transparent—there’s no such thing as “high quality at rock-bottom prices.” So-called “ultra-low-price inks” are just scams: short-term savings for long-term pain.

At our company, we stick to the principle: “Quality is our lifeline; reputation is our future.” We never cut corners with materials or lie about performance. For us, short-term profits don’t matter—we’re committed to delivering high-quality, cost-effective inks that let you print with confidence, every time.