SUPERINKS: A Glimpse into the Production Workshop – Grinding Process: Precision Grinding for High-Quality Digital Inks

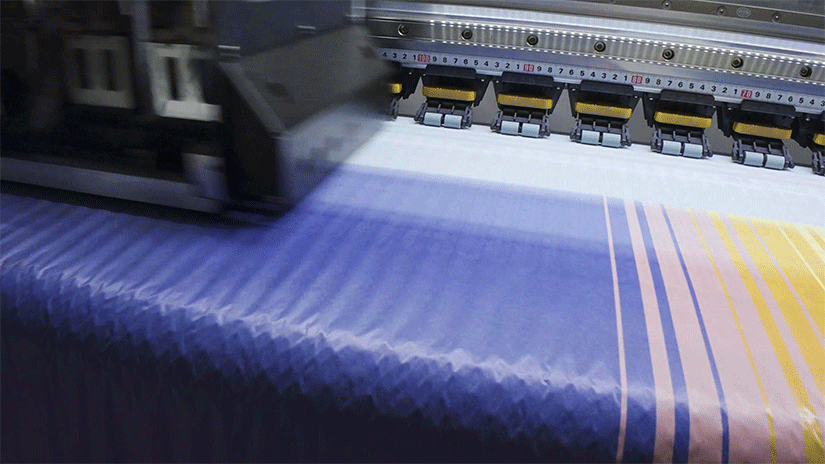

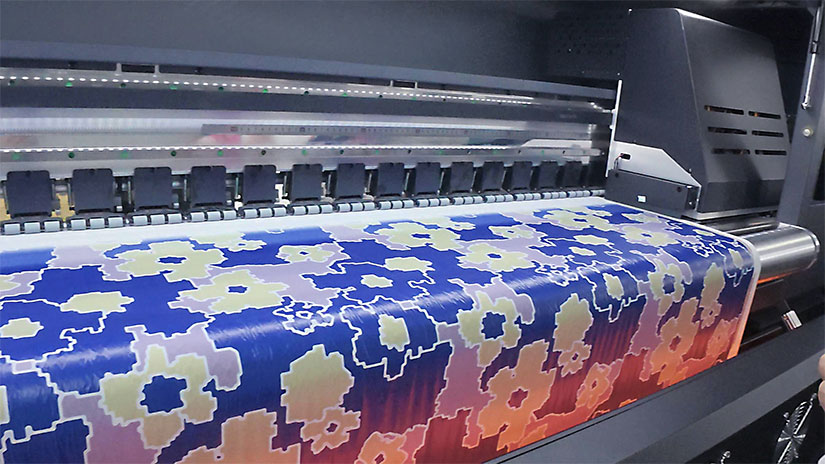

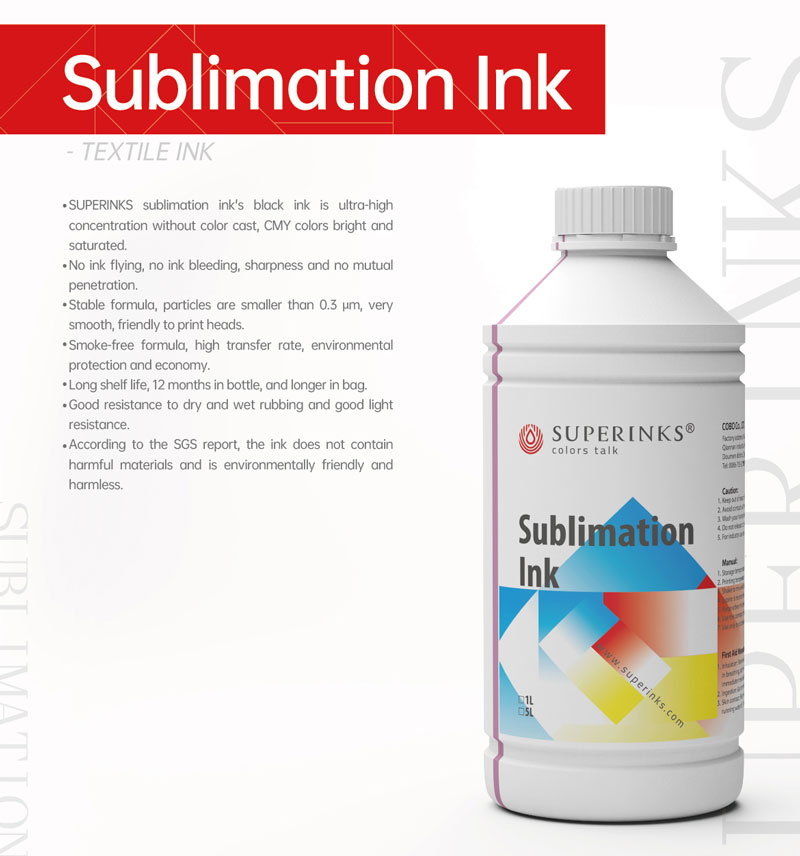

As a professional R&D and manufacturing company specializing in a full range of digital inks, including solvent-based, water-based, DTF, and UV inks, SUPERINKS has always centered on high-quality product delivery to consolidate its market position. The grinding process, a critical link determining ink particle size uniformity, color stability, and printing adaptability, is the top priority of quality control. Today, let’s step into SUPERINKS’ production workshop to unlock the “craftsmanship code of grinding” behind high-quality solvent-based, water-based, DTF, and UV inks.

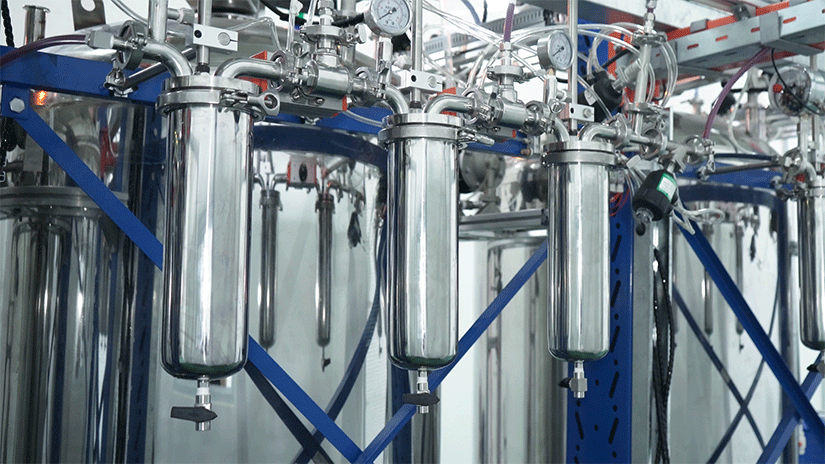

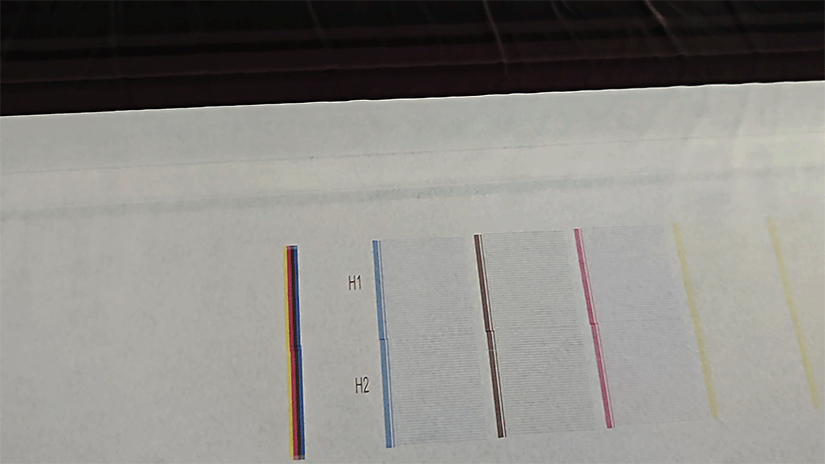

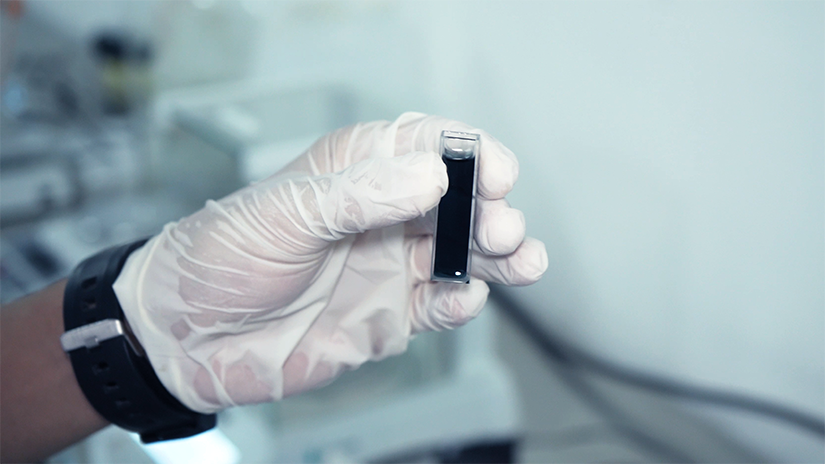

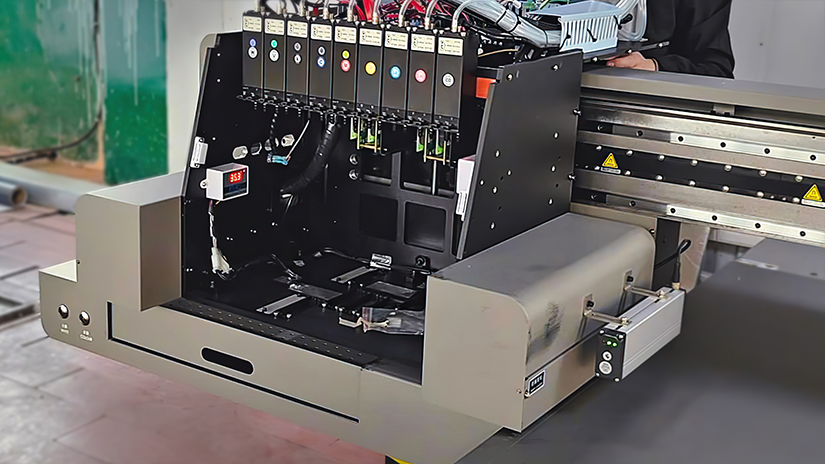

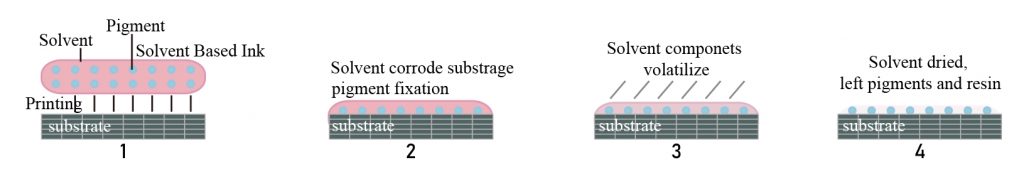

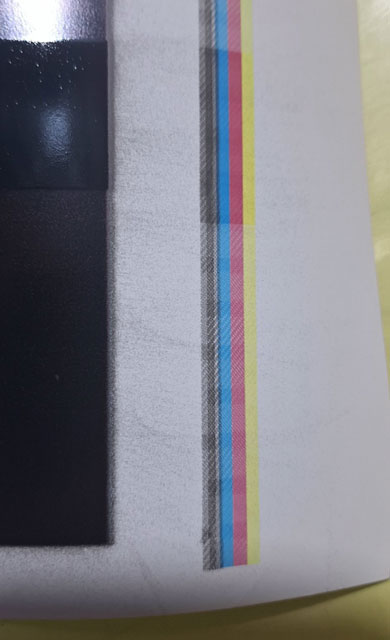

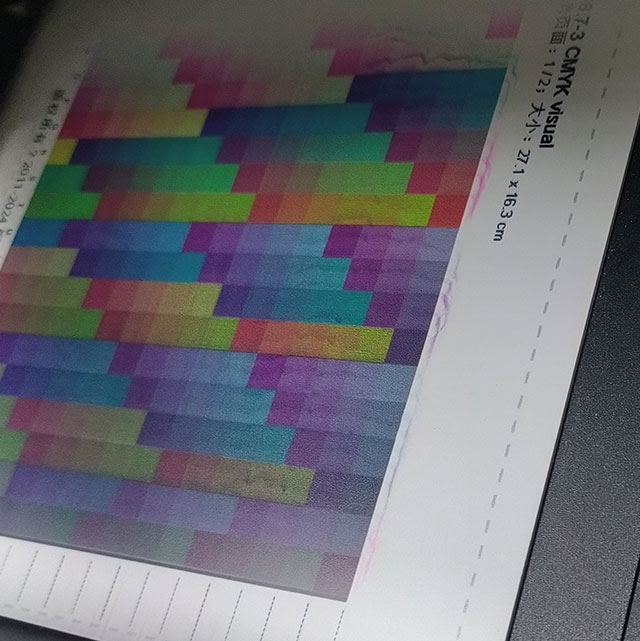

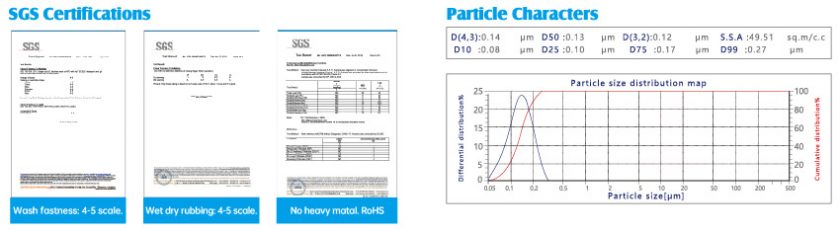

To ensure the superior performance of various inks such as solvent-based, water-based, DTF, and UV inks, SUPERINKS adheres to strict standards in selecting grinding equipment and sources high-quality global equipment to empower production. Inside the workshop, multiple sets of imported Swiss Bühler grinding machines operate stably and efficiently.As a benchmark brand in the global grinding equipment industry, Bühler grinding machines, leveraging their profound accumulation in the ink and coating sector, accurately meet the grinding requirements of various inks, with particularly prominent core advantages. Relying on the revolutionary dual technology of MacroMedia pre-dispersion and MicroMedia+ precision grinding, the equipment can effectively solve the agglomeration problem of various ink raw materials (especially organic solutes in solvent-based inks and photo-curable resin particles in UV inks), grinding the raw materials to a uniform nano-scale particle size with a highly concentrated particle size distribution.

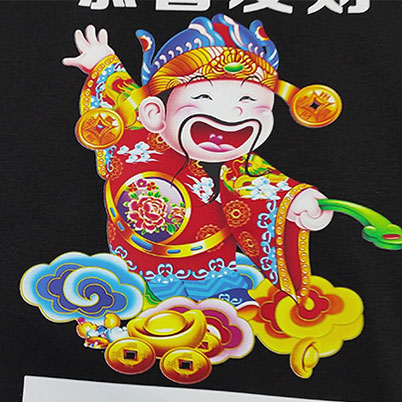

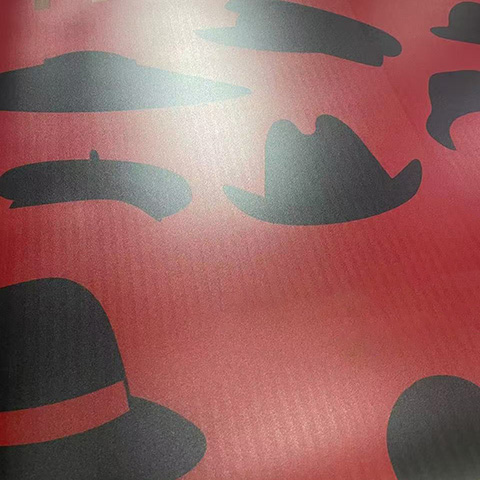

This core advantage is crucial to the performance of various inks: it not only ensures the fast-drying property and weather resistance of solvent-based inks, the environmental safety and dispersion stability of water-based inks, improves the curing speed and adhesion strength of UV inks, but also guarantees the fineness and scrub resistance of DTF ink printing patterns.Meanwhile, the equipment is equipped with a high-precision roller gap adjustment and intelligent temperature control system, which can real-time monitor and stabilize grinding parameters. Even during 24/7 continuous operation, it maintains extreme stability, effectively avoiding issues such as UV ink resin denaturation and solvent-based ink performance deviation caused by temperature fluctuations. More notably, its integrated intelligent control system supports remote monitoring and precise parameter adjustment, which can flexibly adapt to the grinding needs of different types of inks. Combined with an energy-efficient drive design, it improves production efficiency while significantly reducing energy consumption, providing a reliable guarantee of high quality, high efficiency, and cost-effectiveness for the grinding process of various inks at SUPERINKS, and laying a solid foundation for the smooth progress of subsequent processes.

At the same time, SUPERINKS has introduced supporting equipment, including Sanxingfeirong equipment (a leading Chinese brand) and horizontal grinding machines, to build a multi-dimensional and high-efficiency grinding production system. Among them, Sanxingfeirong equipment, with its precise adaptability to domestic production scenarios and excellent grinding performance, can specifically improve the grinding efficiency of solvent-based and DTF inks; horizontal grinding machines, relying on their unique structural design, achieve full grinding and uniform mixing of materials, further enhancing the uniformity of water-based and UV inks, and comprehensively meeting the personalized production needs of different types of digital inks such as solvent-based, water-based, DTF, and UV inks.

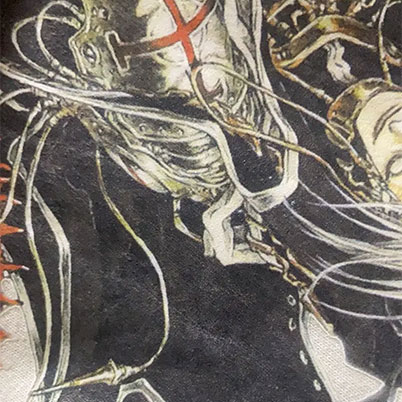

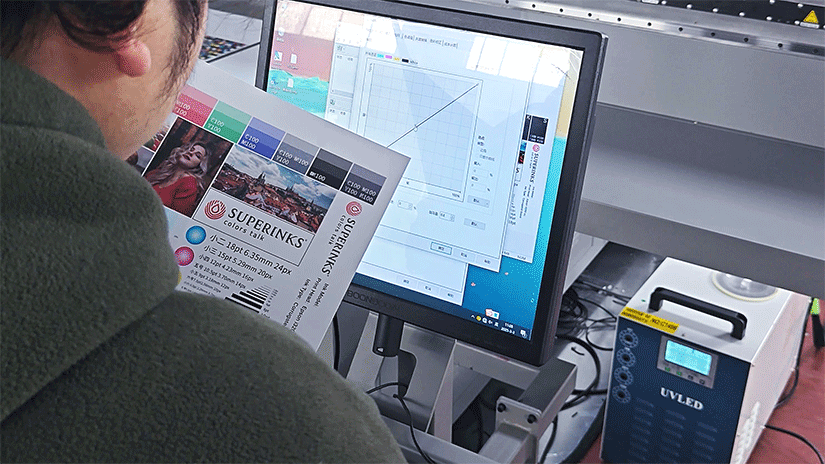

The synergy between high-quality equipment and a professional production team has enabled SUPERINKS to form a unique competitive advantage in the grinding process of solvent-based, water-based, DTF, UV, and other inks. From raw material input to the completion of grinding, technical personnel accurately control every parameter and carefully inspect every link according to the characteristics of various inks, which profoundly interprets SUPERINKS’ pursuit of extreme high quality. In the future, SUPERINKS will continue to uphold the spirit of craftsmanship, take advanced production equipment as the support and strict quality control as the guarantee, continuously deliver more high-quality solvent-based, water-based, DTF, UV, and other ink products to the market, and fully empower the innovative development of digital printing in multiple industries such as textiles, advertising, packaging, and building materials.