About Ultra vibrant colors in sublimation ink direct print flag fabric:

This topic is always the focus of attention in the industry. The hope is that the sublimation ink can be printed directly on chemical fiber fabrics, eliminating the need for a transfer process.

The current mature process requires sublimation ink to be printed to transfer paper, then transferred to the fabric through hot pressing.

However the transfer paper is very costly, and after the transfer, it becomes waste material and is thrown away, which is not environmentally friendly. There are also more processes, each process needs to adjust parameters, which creates multiple variables and it is easy to cause problems and fail to achieve the desired results. In addition, the step of printing ink onto paper and then transferring it also easily causes problems, and the ink loss is large, and the transfer rate is not enough, resulting in waste and environmental problems.

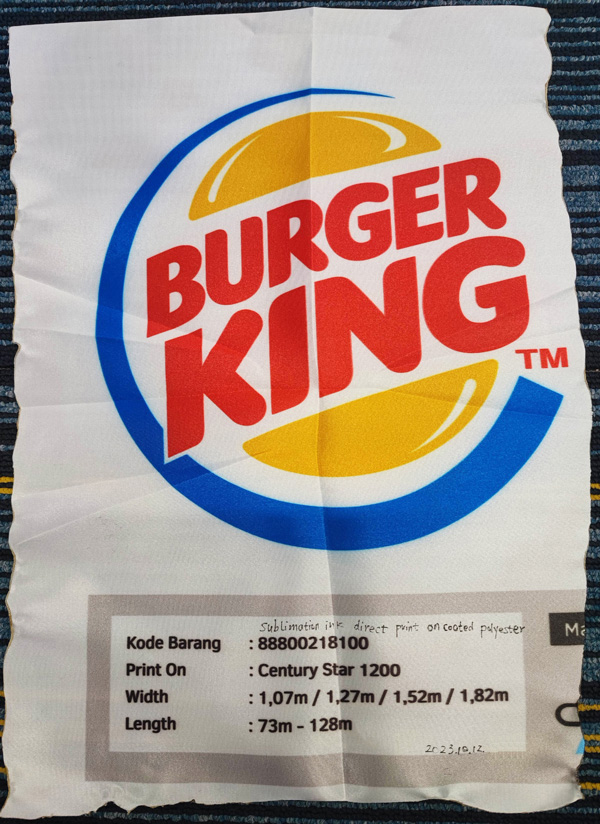

The direct inkjet sublimation ink process solves these problems. However, this process requires the print on pure polyester fabrics(also known as chemical fiber fabrics, without any chemical components such as silicone oils or phosphors). After sizing and drying, the polyester fabric is printed directly with sublimation inks and then dried by a drying unit underneath the printer, which can get ultra-vibrant colors without heat pressing. This process is more in the way with future trends.

The technology actually appeared more than a decade ago, with initial tests targeting advertising banners as a product, but the colors printed on fabric were not vibrant enough. So people defined it as low-grade printing. The ink used in the tests for low-grade printing was not concentrated enough, resulting in poor color performance.

Technological Improvement Points:

Progress in two key points improves the effect of the sublimation ink direct injection process:

Firstly, sublimation inks must be used at high concentrations to achieve sufficiently vibrant results on fabric.

Secondly, the coatings developed for sublimation inks have been greatly improved.

It is now possible to print very vibrant and beautiful results using high-concentration inks to produce high-quality outdoor advertising products.

Sublimation Ink Direct Print Application Status:

Can Sublimation Ink Direct Print technology be applied in the garment industry now?

In the current situation, the softness of the pre-treat solution still needs to be further improved to meet the softness requirements of the fabric after sizing. Therefore, at present, sublimation technology is mainly applied to the production of advertising banners, as it doesn’t require high softness, but only needs to ensure that the colors can be firmly adhered to the fabrics to achieve vibrant color performance.

Will sublimation technology be used in the garment industry in the future?

It is very possible that the sublimation technology will be applied to the garment sector in the future.

The key is that the fabrics treated with the pre-treatment solution need to have qualified softness and be able to carry the direct inkjet process well, as well as having good color fade resistance.

Only in this case, sublimation technology can be further applied and developed in the garment sector.

The future direction of development:

The current process of Sublimation Ink Direct Print for advertising banners still has a fatal drawback:

the color powder used in the ink has a short sunlight resistance time outdoors. Therefore, sublimation technology is not recommended for long-term outdoor advertising. However, for short-term advertising applications such as exhibitions or sports events, it’s a very good choice, because the sublimation ink direct inkjet process technology has excellent color performance and lower cost.

Overall, the emergence of the direct inkjet sublimation ink printing process has brought new development opportunities to the garment industry.

Although there are still problems in improving the softness and sunlight resistance of the ink. With the continuous development and improvement of the technology, sublimation technology is expected to be more widely used in the garment and outdoor advertising fields in the future.

This will bring more innovation and possibilities to the garment and advertising industries, as well as provide consumers with more choices and quality product experiences.