Ricoh G6 Leads; Konica & Epson Aim to Carve Niches in Segmented Industrial UV Print Head Market

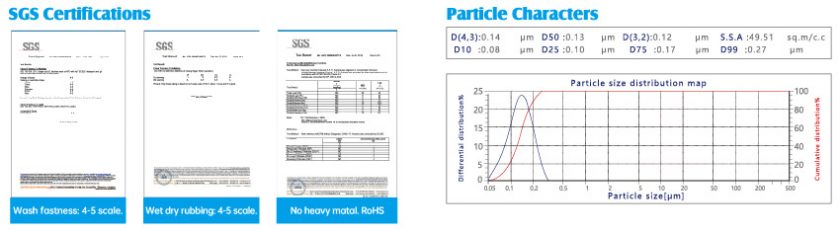

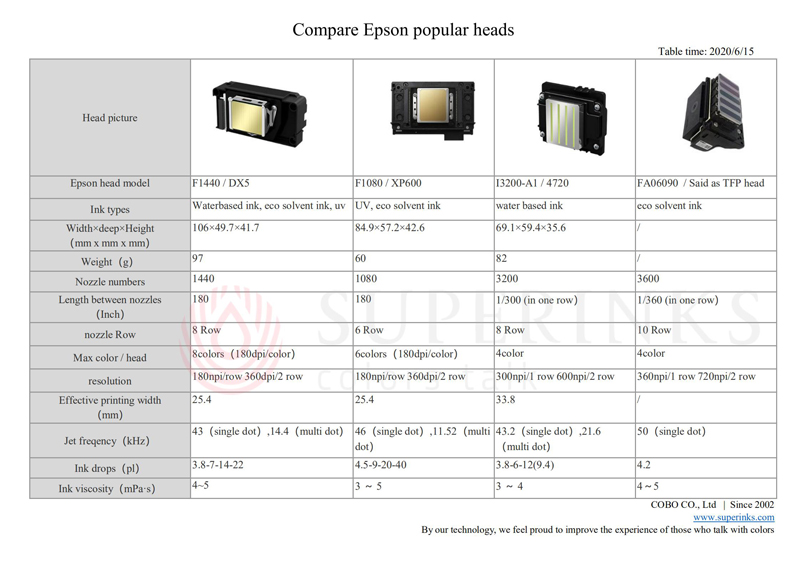

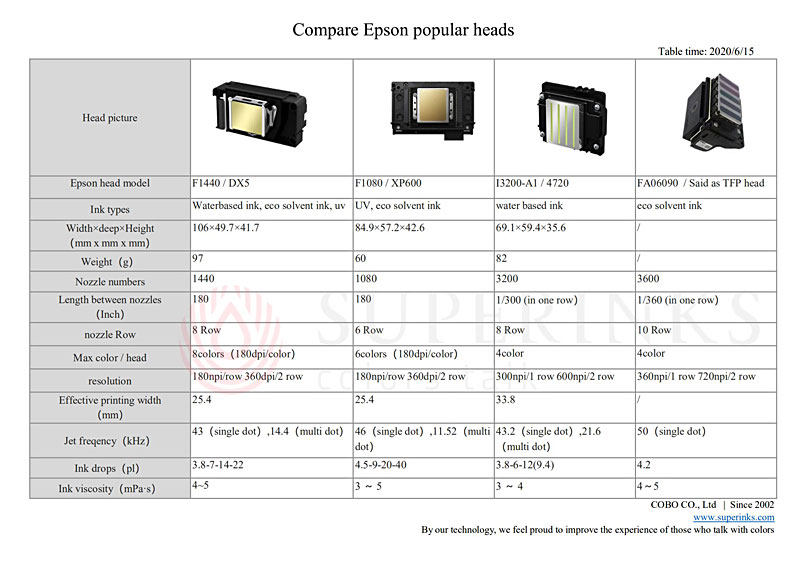

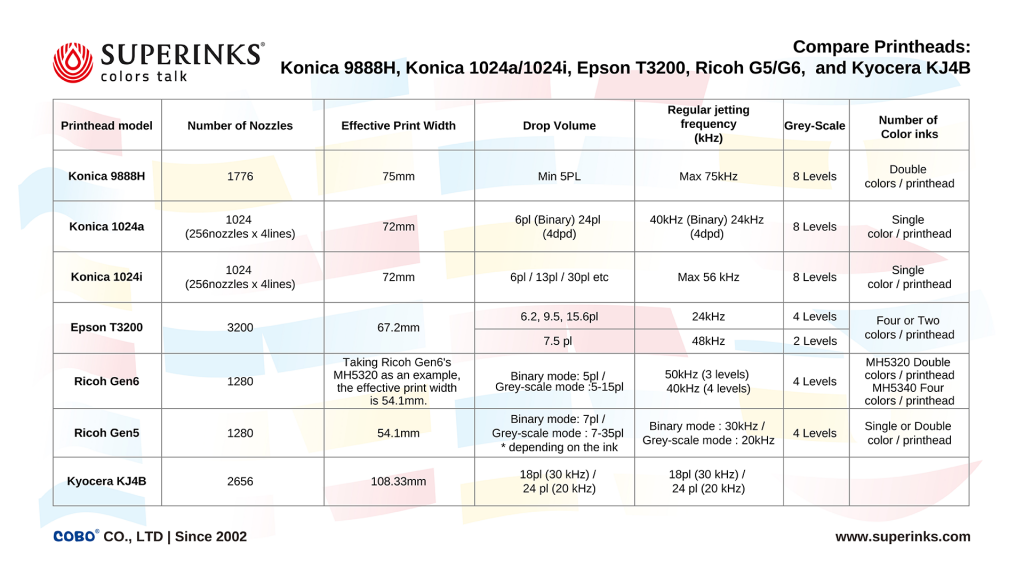

A recent parameter comparison of four leading industrial print heads—Konica 9888H, 1024i/1024a, Ricoh G6, and Epson T3200— For ink manufacturers, such parameter differentiation also underscores the criticality of tailored ink solutions—our company, with years of expertise in industrial printing ink R&D, has been at the forefront of developing compatible inks that unlock the full performance potential of these mainstream print heads. Meanwhile, the industry’s ongoing debate over whether any print head can outperform the Ricoh G6 in overall performance has become increasingly settled as market feedback accumulates.

Ricoh G5/6 Retains Unrivaled Comprehensive Advantages as Industry Benchmark

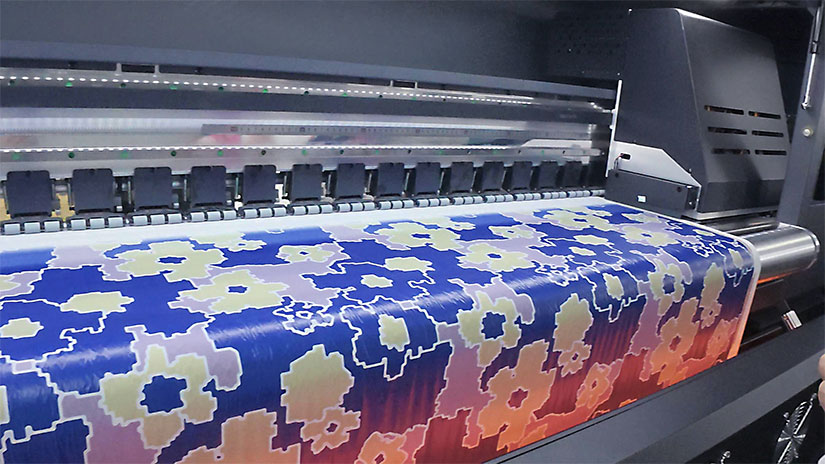

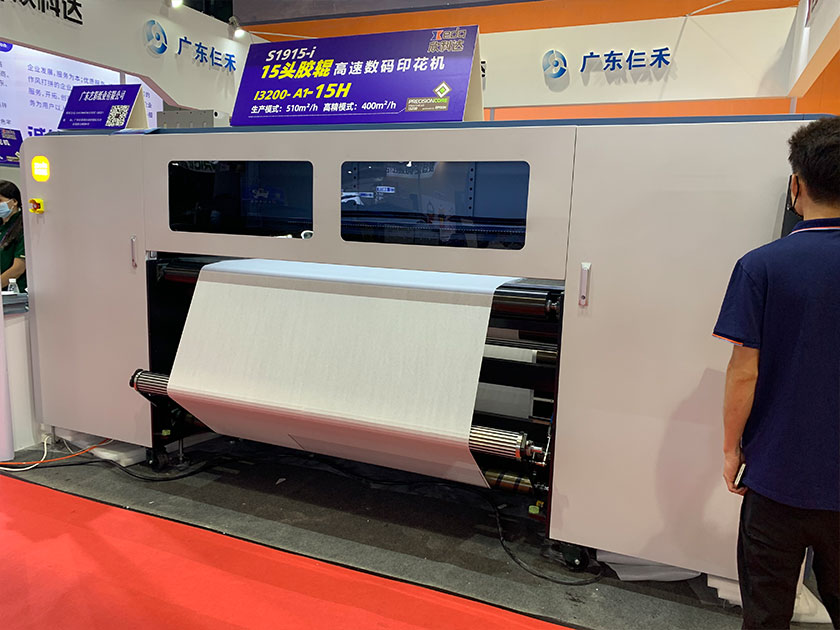

Parameter comparisons and real-world application data confirm that the Ricoh G5/6 series remains the gold standard for all-around performance in industrial printing. Its core strengths stand out in three key areas: first, exceptional versatility—seamlessly compatible with UV, solvent-based, and water-based inks, it serves diverse sectors from advertising and packaging to building materials and textile printing, eliminating the need for frequent head replacements to meet varied production demands. Our specially formulated inks for Ricoh G5/6 have been widely recognized for enhancing color vibrancy and extending head lifespan, further amplifying the series’ advantages in multi-scenario applications. Second, superior reliability—its failure rate during long-term continuous operation is well below industry averages, minimizing equipment downtime for maintenance. Third, balanced efficiency and quality—its high-speed printing capabilities paired with excellent color saturation align perfectly with industrial production’s core requirement for “high throughput + consistent quality.”

Industry technicians widely acknowledge that while some print heads excel in individual metrics—such as jet frequency or droplet precision—none have matched the Ricoh G5/6’s all-around performance to date. However, as the industrial printing sector pushes toward higher precision, greater throughput, and lower operational costs, equipment manufacturers are raising the bar for print head performance. There is a pressing demand for a next-generation print head that delivers breakthrough all-around capabilities, supporting multi-scenario compatibility while boosting productivity and cutting operational expenses. This need continues to drive technological innovation across the industry.

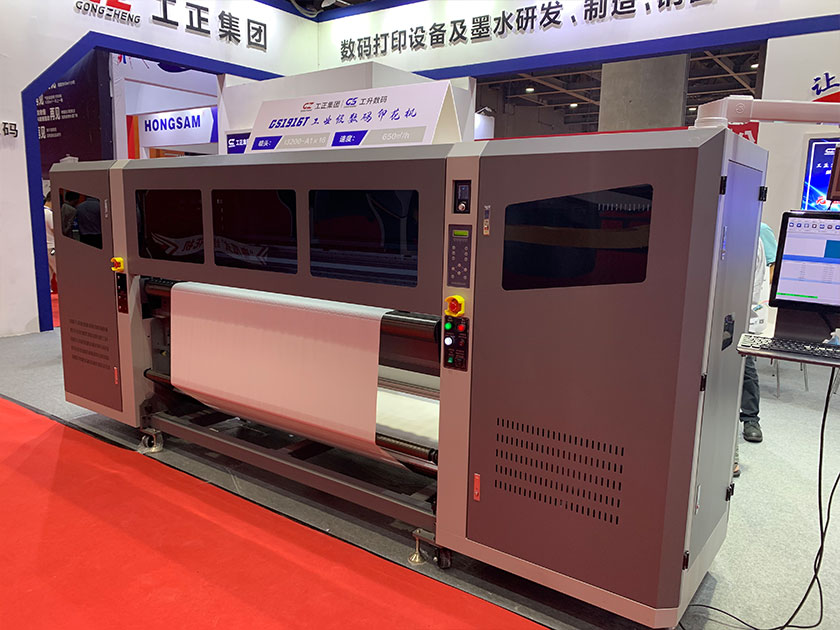

Konica 9888H & Epson T3200: Carving Out Niche Markets with Differentiated Strategies

With Ricoh G5/6’s dominant all-around performance unlikely to be dethroned anytime soon, companies like Konica and Epson are focusing on niche market penetration. Through tailored parameter designs and technical refinements, they aim is established unique market positions—with the Konica 9888H and Epson T3200.

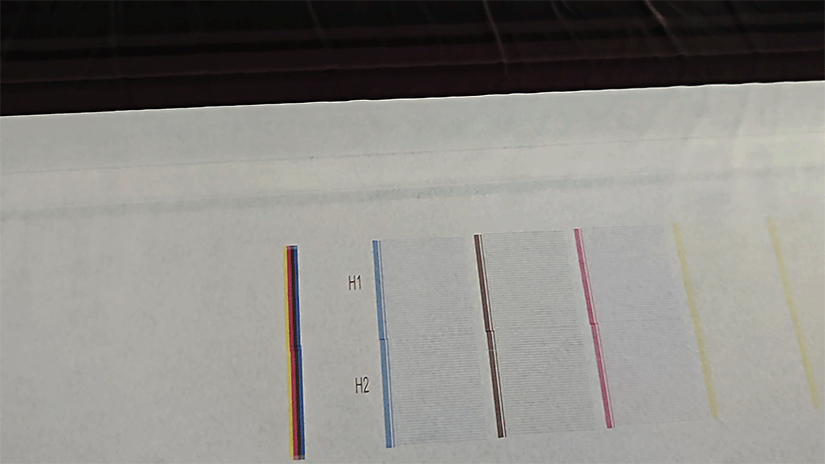

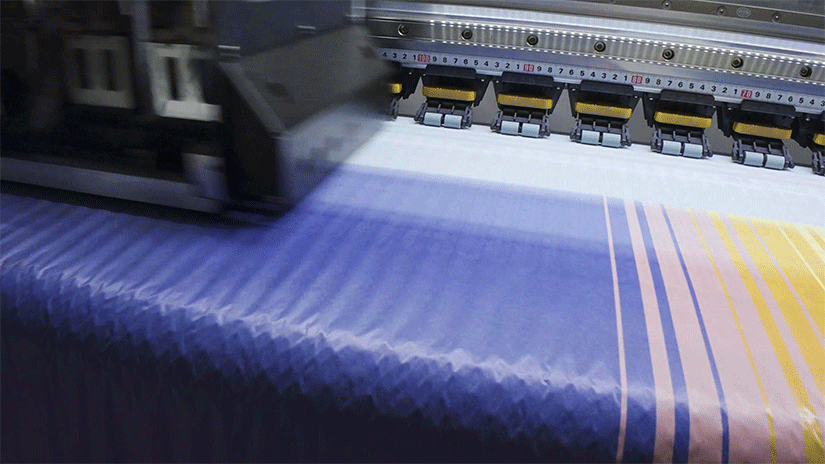

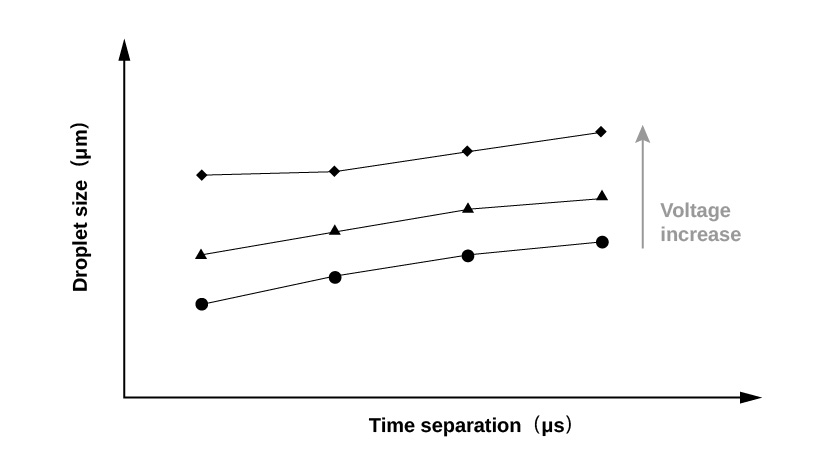

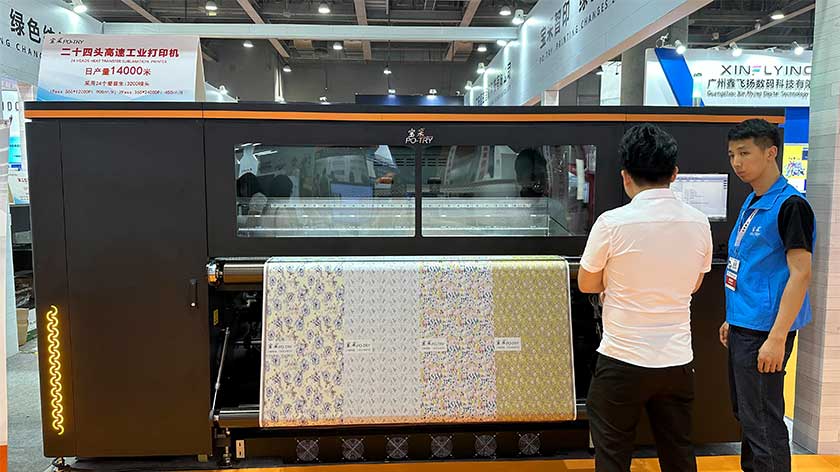

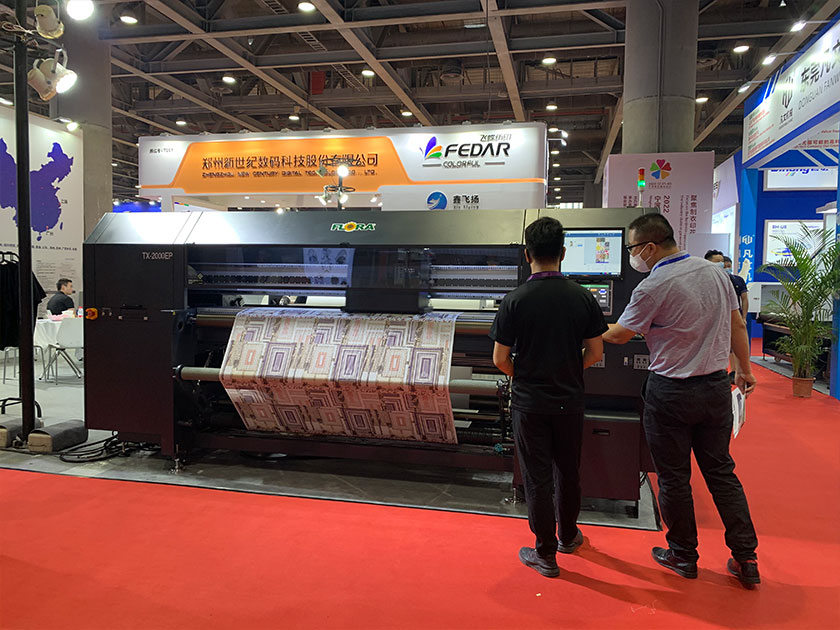

The Konica 9888H distinguishes itself with a core parameter set of “small droplets + high firing frequency.” Equipped with 1,776 precision nozzles and offering a 75mm effective print width, it supports single-head dual-color printing. Boasting a minimum droplet size of 5PL and 8-level grayscale technology, it delivers exceptional clarity for fine lines and small text. Meanwhile, its maximum jet frequency of 75kHz enables significantly higher throughput than traditional print heads, making it ideal for large-format batch printing applications.

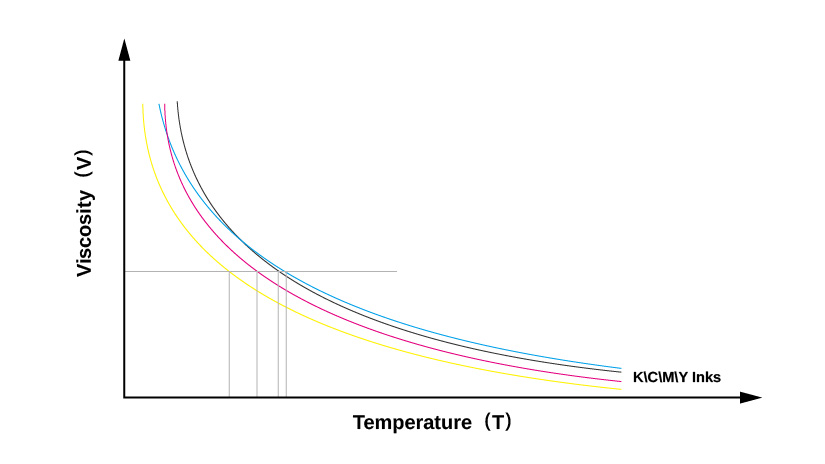

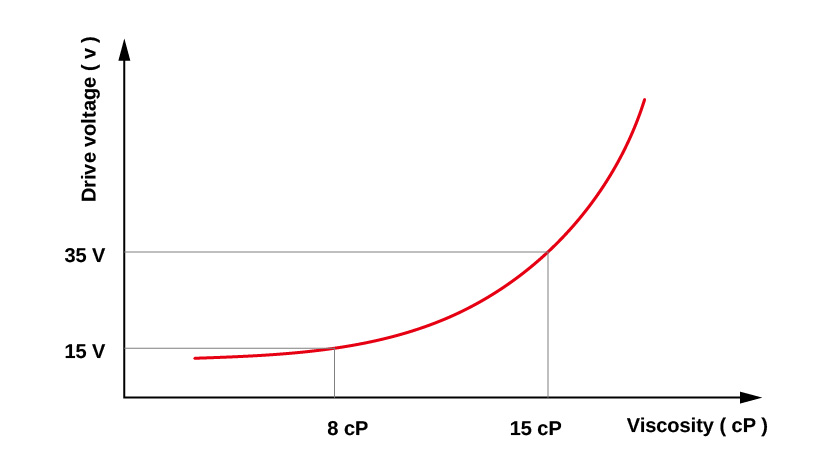

For UV ink compatibility, the Konica 9888H requires specialized high-viscosity UV ink that is incompatible with those designed for Konica 1204i/a or Ricoh G5/6 heads. To address this, our team has developed a dedicated UV ink formula for Konica 9888H, which not only meets the 3.5PL minimum droplet flow rate requirement but also effectively prevents nozzle clogging and uneven ink deposition—key pain points in industrial production. For eco solvent inks, the 9888H retains its “high viscosity + fast flow rate” advantages (critical for continuous industrial printing and throughput) while featuring enhanced standby moisturization capabilities. Our matching eco solvent inks complement these strengths, ensuring consistent output even during long production runs.

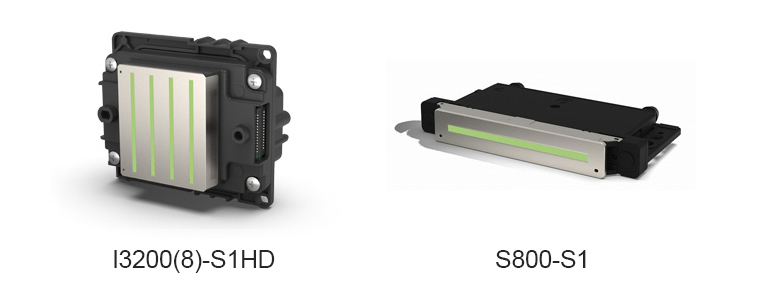

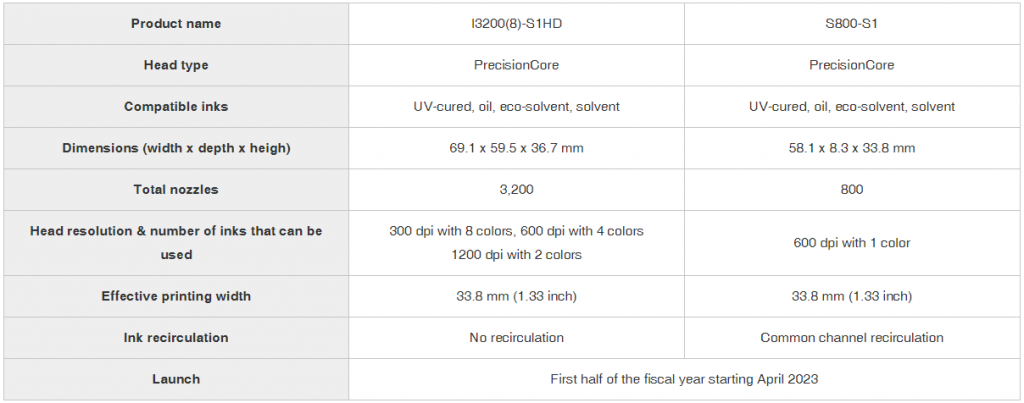

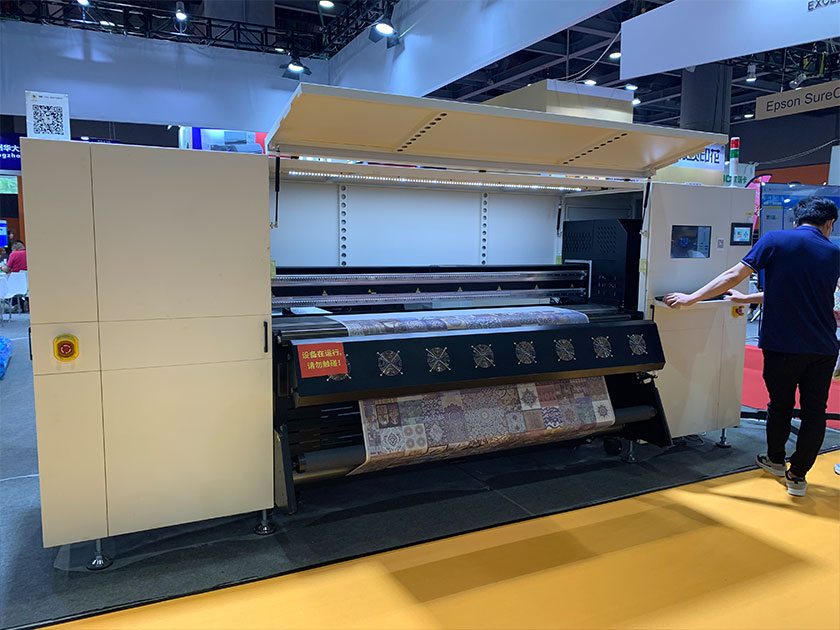

The Epson T3200, meanwhile, aims to secure a separate niche with its strengths in “high nozzle density + consistent output.” Featuring 3,200 nozzles and a 67.2mm effective print width, it supports flexible configurations of 4 colors or 2 colors per head. With droplet size options ranging from 6.2PL to 15.6PL, it adapts seamlessly to printing scenarios with varying precision requirements.

Industry Trends:

Dual Drivers of Niche Innovation and Comprehensive Upgrades Today’s industrial print head market features a clear competitive landscape: a dominant all-around benchmark alongside rising niche specialists. The Ricoh G5/6 series sets the technical standard for the industry and will remain the top choice for mid-to-high-end multi-scenario applications in the near term. Meanwhile, models like the Konica 9888H and Epson T3200 have solidified their positions in niche segments—including large-format batch printing and mid-to-high-end basic printing—through differentiated technical approaches.

Industry experts note that future print head innovation will focus on two core areas. First, deeper specialization for niche scenarios: customized print head-ink compatibility will become a key competitive differentiator, requiring precise alignment with specific application needs to balance efficiency, cost, and quality. As a trusted partner for industrial printing enterprises, we are committed to co-innovating with print head manufacturers, leveraging our ink formulation expertise to develop tailor-made solutions that keep pace with technical advancements. Second, sustained demand for improved all-around performance: manufacturers will continue pursuing breakthroughs in versatility, reliability, and efficiency, pushing industrial printing technology to new heights. As technology matures and market demands evolve, competition in the industrial print head sector will intensify—ultimately delivering more efficient, precise printing solutions for downstream industries, with high-quality compatible inks playing an increasingly pivotal role.