In digital printers, waveform, temperature, and voltage form an interconnected closed-loop system that collectively determines printhead performance—including droplet precision, stability, and ejection efficiency. Their core relationship: waveform is the control logic backbone, voltage executes the waveform, and temperature indirectly affects their alignment by altering ink and printhead properties. Here’s a concise breakdown:

I. Waveform and Voltage: Direct Instruction-Execution Link

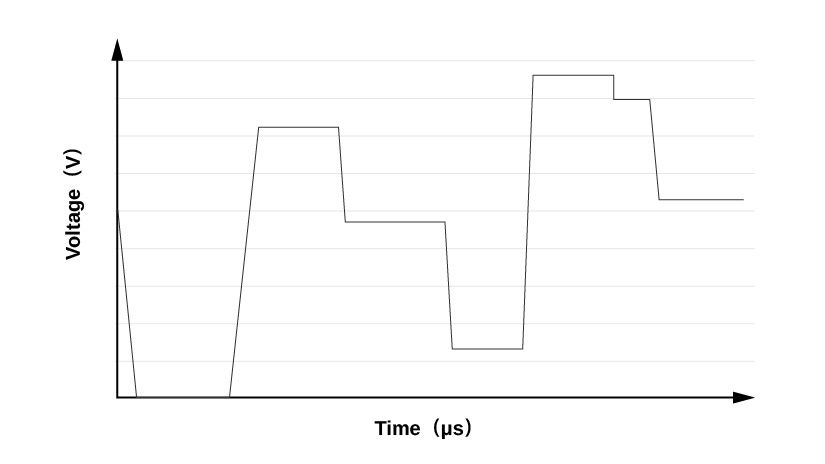

Voltage physically expresses the waveform, with the waveform defining voltage parameters (peak, duration, pulse shape) and voltage output validating the waveform’s effectiveness:

- Waveform dictates voltage’s “time-intensity” profile

A waveform is a voltage-time curve. For example, its “main ejection pulse” uses high voltage (30–50V) to drive piezoelectric crystals, expelling droplets of set volume; a subsequent “damping pulse” (5–10V) suppresses residual vibrations, preventing “satellite droplets.” Voltage peak, timing, and slope are precisely set via waveform parameters (e.g., V1/V2, t1/t2).

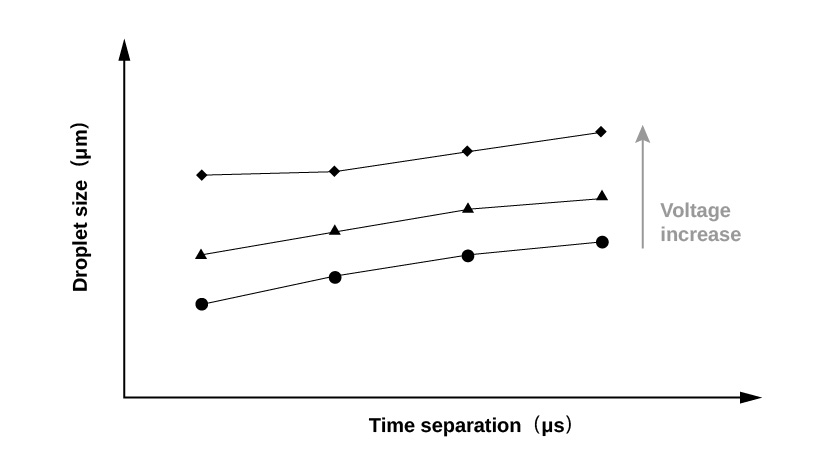

- Voltage must match waveform energy needs

Waveforms rely on voltage to deliver actuation energy (≈ voltage²×time/resistance). Insufficient voltage causes undersized droplets or clogs; excessive voltage risks overheating, printhead damage, or messy droplet spread.

II. Temperature: Indirectly Shaping Compatibility

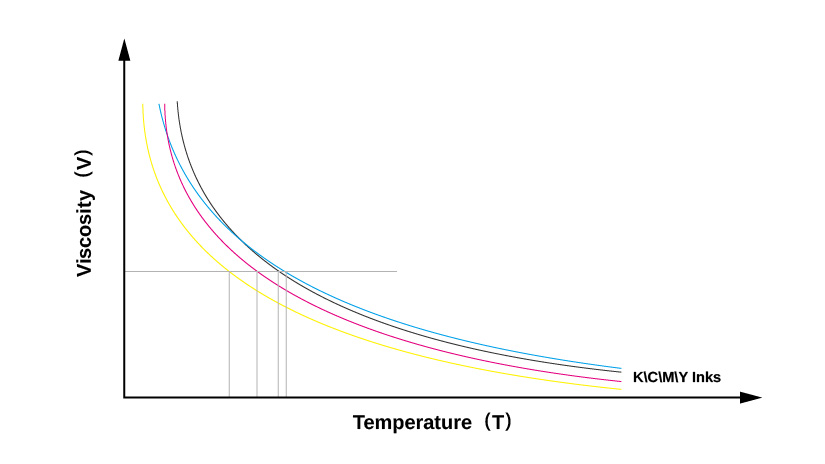

Temperature disrupts waveform-voltage balance by changing ink and printhead properties, requiring adjustments:

- Ink effects:

- High temps (>35°C) thin ink, risking blurred edges or residual buildup. Fixes: shorter pulses, lower voltage, or stronger damping.

- Low temps (<25°C) thicken ink, causing clogs or faint prints. Fixes: longer pulses, higher voltage, or pre-ejection bursts.

- Printhead effects:

High temps make crystals more deformable (amplifying voltage force); low temps stiffen them (weakening force). Thus, voltage/waveform intensity must drop in heat and rise in cold to stabilize droplets.

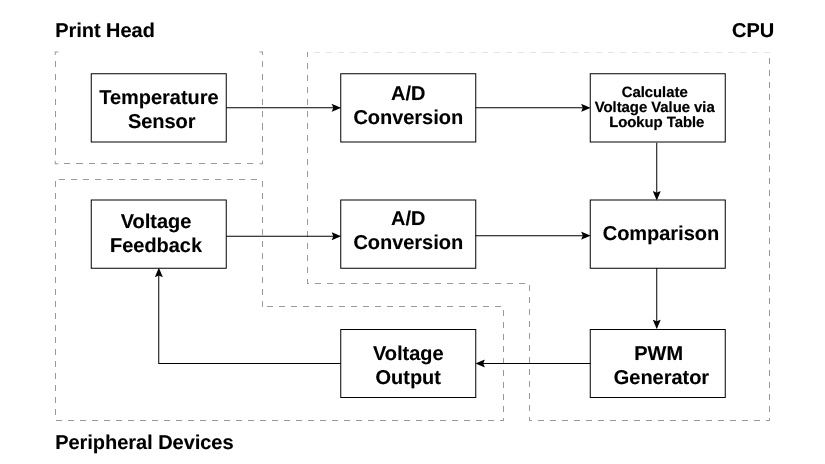

III. Dynamic Balance: Closed-Loop Control

Printers use sensors and algorithms to sync the three:

- Temperature triggers: Sensors (±1°C accuracy) adjust waveform/voltage if temps leave 25–35°C, keeping droplets stable.

- Voltage fluctuations: Algorithms tweak pulse length to maintain energy (longer for low voltage, shorter for high).

- Safety limits: Waveforms cap voltage at high temps (e.g., ≤30V at 50°C) and shorten pulses at high voltage (e.g., 60V) to prevent damage.

Choose SUPERINKS for Seamless Synergy

Ink stability is key—and SUPERINKS excel here:

- Temperature resistance: Proprietary formula limits viscosity swings to ≤8% (35–50°C) and ≤12% (0–25°C), far better than standard inks (20–30%/25%), reducing waveform/voltage tweaks.

- Printhead compatibility: 500+ tests with Epson I3200, Ricoh G5, Konica 1024 ensure perfect surface tension matching, achieving <2% droplet deviation across ±20°C. Crisper details, smoother color transitions.

- Cost/efficiency gains: Stable viscosity cuts voltage adjustments, reducing crystal fatigue by 30% (extending printhead life by 4,000 hours) and lowering waste/operational costs by 15–20%.

Summary

Waveform = “blueprint,” voltage = “force,” temperature = “environment”—SUPERINKS harmonize them all. Choose us for precise, efficient, cost-effective printing.