In inkjet printing operations, have you ever been puzzled by this scenario: despite selecting ink labeled “high-quality raw materials” and “fine grinding”, you still face frequent issues such as printhead clogging, skewed jetting, ink spattering, and the need for frequent printhead cleaning and maintenance? In reality, the root cause of these problems often lies in a critical yet easily overlooked step — ink filtration.

Today, we will explore in depth the importance of “filtration” to inkjet ink quality and how to identify truly high-quality ink using “filtration standards”. This knowledge will help you avoid production pitfalls, boost printing efficiency, and enhance the quality of finished products.

I. First, Understand: Why Is Filtration Essential for Inkjet Ink?

To fully grasp the core value of filtration, it is first necessary to recognize the “unique technical requirements” of inkjet printing — the orifice of an inkjet printhead is extremely small, typically only tens of micrometers (roughly 1/10 the diameter of a human hair). This characteristic means that even microscopic impurities invisible to the naked eye (such as incompletely ground pigment particles, residual dust from raw materials, and debris introduced during production) can become trapped in the printhead orifices, leading to a range of production issues:

- Printhead Clogging: Impurities blocking the orifices directly cause ink breakage and spattering. Not only does this require production halts for printhead disassembly and cleaning, but repeated unclogging also wears down the printhead, shortening its service life. (High-quality inkjet printheads are often costly, and frequent replacements can significantly increase production expenses.)

In short, the primary function of filtration is to “completely remove all types of impurities from the ink”, providing a core guarantee for the “purity” and “stability” of the ink. This is the fundamental prerequisite for achieving stable, efficient inkjet printing operations.

II. Evaluate Quality: What Standards Define Effective “Filtration” for High-Quality Ink?

Once you understand the importance of filtration, the next critical question is: how to determine if an ink’s filtration process meets high standards? In fact, truly high-quality inkjet inks must satisfy three core criteria in their filtration processes, which can be summarized as the “Three Pillars of Filtration”:

Pillar 1: Filter Cartridge Selection — Is a “Reliable Core Filtration Component” Used?

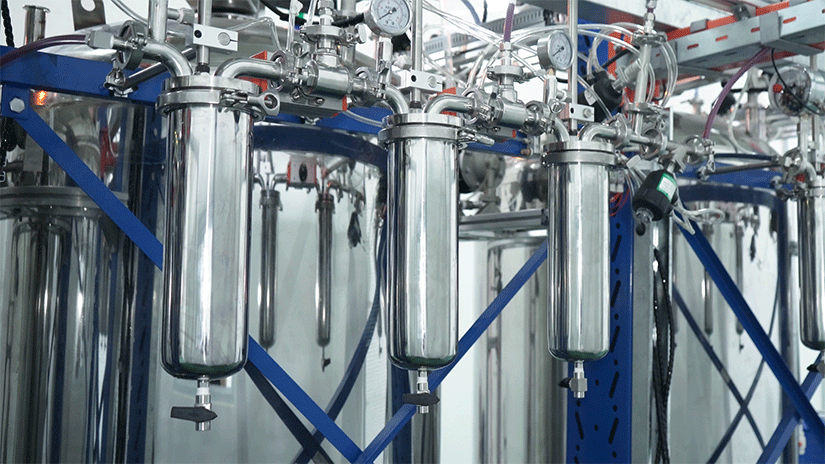

The filter cartridge is the “heart” of the filtration system, and its quality directly determines filtration performance. Currently, many ordinary inks on the market use low-cost, general-purpose filter cartridges to cut costs. These cartridges have low filtration precision and poor chemical resistance, and their efficiency tends to degrade and fail over time. In contrast, high-quality inks prioritize professional industrial-grade filter cartridges, particularly those from well-known brands validated in industries with strict purity requirements, such as semiconductors and pharmaceuticals.

For instance, in our production process, we exclusively use industrial-grade filter cartridges from two globally renowned brands: Cobetter and PALL. These cartridges offer three key advantages:

- “High-Precision Retention”: Capable of accurately capturing micrometer-scale impurities and effectively blocking tiny particles;

- “Strong Chemical Resistance”: Compatible with various inkjet ink formulations (including solvent-based, water-based, and UV-curable inks) without deformation, slagging, or other issues caused by ink corrosion;

- “Stable Performance”: Maintains consistent filtration efficiency during long-term use, ensuring uniform purity in every drop of ink.

Therefore, when selecting ink, we recommend proactively asking about “the brand and grade of the filter cartridges used” — this is the primary indicator for assessing the filtration quality of the ink.

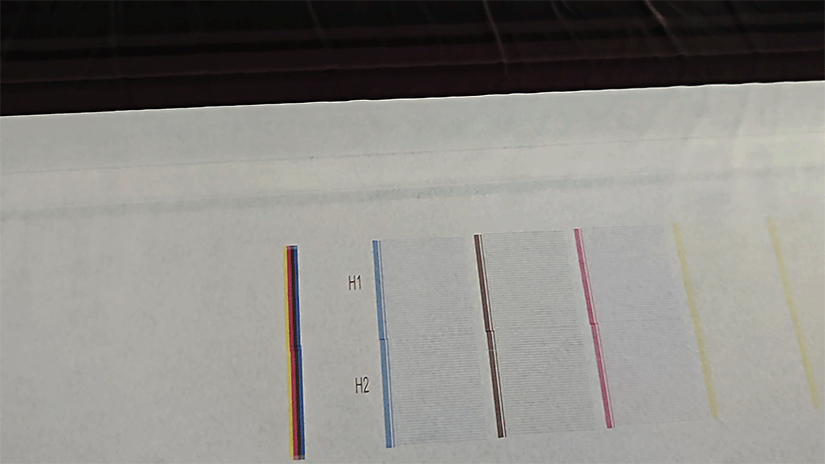

Pillar 2: Filtration Process — Is “Comprehensive, Multi-Layered Purification” Achieved?

Relying solely on high-quality filter cartridges is insufficient for thorough, efficient filtration; the scientific design of the filtration process is equally critical. Some inks use a “single-stage filtration” process, which only removes larger particles, leaving finer impurities behind. A truly effective filtration system, however, requires a “progressive multi-stage filtration” process — analogous to “first sieving sand, then sifting fine soil, and finally filtering out dust” — to ensure complete removal of impurities from the ink.

Our three-stage recirculating filtration system is a prime example of this progressive purification approach:

- “Coarse Filtration Stage”: Prioritizes the removal of large particle impurities in raw materials (such as poorly dispersed pigment clumps) to prevent damage to subsequent precision filtration components;

- “Fine Filtration Stage”: Further eliminates fine dust and small, incompletely ground pigment particles, improving the uniformity of particle distribution in the ink;

- “Ultra-Fine Filtration Stage”: Finally traps trace impurities invisible to the naked eye (such as micrometer-scale dust), elevating ink purity to meet the strict requirements of high-standard inkjet printing.

Practical testing confirms that after adopting the three-stage recirculating filtration system, the rate of printhead clogging caused by ink is reduced by over 90%.

Pillar 3: Replacement Standards — Is a “Strict Filter Cartridge Replacement Mechanism” in Place?

Filter cartridges naturally wear out during use, and their filtration efficiency declines over time — this is an unavoidable reality. However, some manufacturers delay cartridge replacement based on “subjective experience” to reduce costs, resulting in lower ink purity in later production batches and inconsistent quality across batches.

In contrast, manufacturers of high-quality ink establish standardized filter cartridge replacement mechanisms, relying on data rather than “subjective judgment”. For example, our established standard is: mandatory filter cartridge replacement after every 400kg of ink produced. Regardless of the cartridge’s appearance or perceived usability, once this production threshold is reached, the cartridge is immediately replaced with a new one. This measure ensures that the filtration effect of each ink batch remains optimal, fundamentally eliminating the issue of “batch-to-batch quality fluctuations”.

For you, consistent ink quality across batches means: no need to worry about “the current batch performing well, while the next batch has issues”. This enables more stable standardized production and reduces production risks associated with ink quality variations.

III. Key Benefits: What Practical Production Issues Does “Filtration-Qualified” Ink Solve?

At this point, you may wonder: what practical value does understanding filtration and choosing filtration-qualified ink bring to my production? In summary, its core benefits are reflected in three key areas:

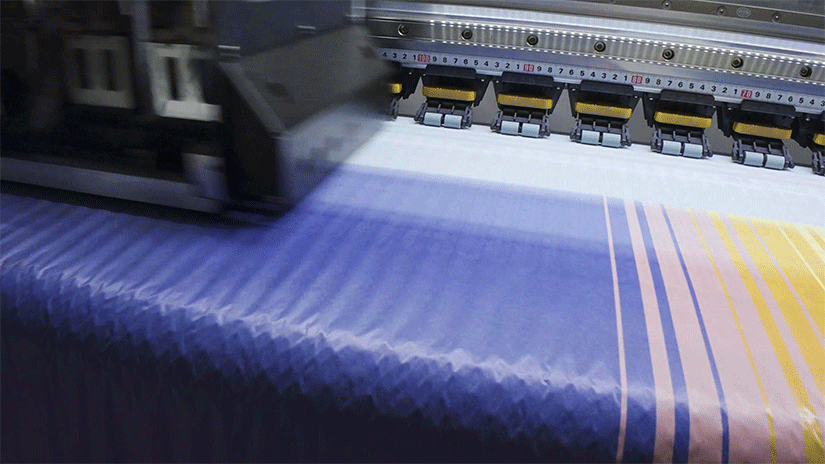

- Lower Production Costs: Reduced printhead clogging frequency not only cuts printhead maintenance costs but also significantly extends the printhead’s service life, lowering expenses related to printhead replacements;

- Higher Production Efficiency: Minimizes production downtime caused by ink-related issues, ensures smooth printing processes, and shortens production cycles;

- Superior Finished Product Quality: High-purity, stable ink delivers uniform print colors and sharp patterns, ensuring consistent finished product quality. This improves customer satisfaction and strengthens your brand’s competitiveness.

Final Thought: Valuing Filtration Means Valuing Your Production Value

While “filtration” may seem like a minor detail in ink production, it directly impacts your production efficiency, cost control, and finished product quality. We hope this overview helps you gain a deeper understanding of the importance of ink filtration and provides an additional “professional evaluation criterion” when selecting inkjet ink in the future.

If you encounter issues related to “filtration” or other technical challenges during ink selection or use, please feel free to contact us at any time. We are not only committed to providing high-quality inkjet ink but also aim to be your “printing technology partner” — working together to solve practical production problems and jointly enhance printing quality and efficiency.