Recently, the sales and technical teams of SUPERINKS have formed a special service group, which has proceeded to the sites of terminal customers of agents across various regions to conduct inspections of ink usage and provide technical support. This initiative not only manifests the company’s high emphasis on product quality and customer experience, but also implements the “customer-centered” service philosophy through concrete actions.

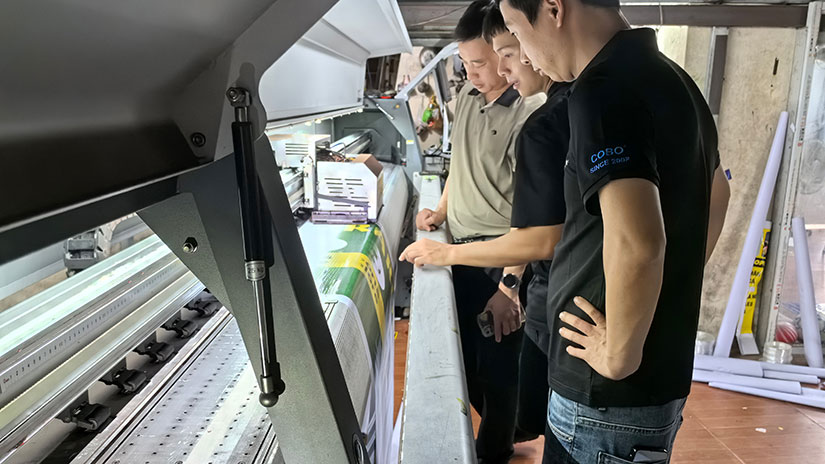

As a professional ink manufacturer, SUPERINKS has always held the conviction that high-quality products are reliant on a sound service system. During this visit, team members have penetrated into the production workshops of terminal customers such as outdoor advertising sign enterprises and garment manufacturing companies, to conduct on-site observations of the application status of the company’s inks under different equipment and production processes. Every detail, ranging from the on-machine debugging parameters of the ink to the color rendering effect of printed products, and from the storage conditions, usage environment of the ink to the consumption during the production process, has been incorporated into the inspection scope, aiming to fully grasp the actual performance of the products in practical applications.

In response to various usage difficulties raised by customers, the technical team has exhibited solid professional proficiency. Some customers have anticipated achieving more desirable printing colors, and the technicians promptly provided ICC file production services. By virtue of I1 pro professional equipment for color collection and analysis, and through precise adjustment of parameters in light of customers’ usage habits and the characteristics of printing materials, they ultimately assisted customers in achieving accurate color matching. Additionally, some customers have reported issues such as wire breakage and ink bleeding during the printing process. Team members have conducted a thorough check of key indicators including static electricity, ink supply system pressure, nozzle temperature, and waveform, rapidly identified the root causes of the problems, and put forward targeted solutions, which have facilitated the swift recovery of production efficiency.

“It never occurred to us that the manufacturer would take the initiative to come to our premises to solve problems; such service is truly considerate!” The person in charge of a terminal customer expressed sincere appreciation during the visit. The sales team has taken this opportunity to engage in in-depth communication with customers, meticulously recorded their suggestions regarding product performance, delivery cycles, and other aspects, and collected first-hand information for the company’s subsequent product upgrading and service optimization.

This terminal visit activity has not only effectively addressed the practical difficulties encountered by customers in the process of ink usage, but also narrowed the distance between the company and terminal users. SUPERINKS will continue to adhere to its core values of “Listen to customer requirements, and create value for customers. To embrace and guide updates.” Through regular customer visits and technical support, it will continuously enhance product competitiveness and customer satisfaction, strive for win-win outcomes with extensive partners, and jointly create a promising future for the ink industry.