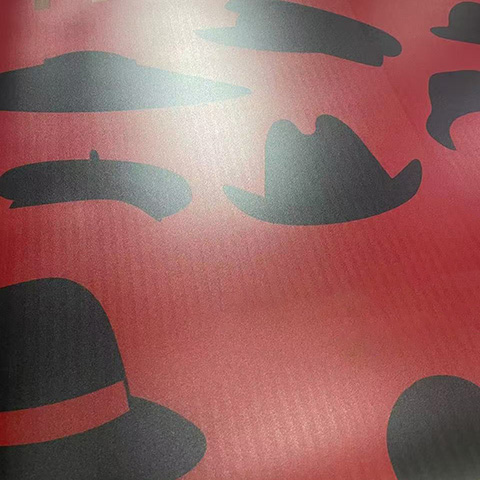

The pass-through phenomenon in UV flatbed and roll-to-roll printers—particularly noticeable when printing solid colors—stems from unavoidable mechanical precision errors.

Theoretically impossible to eliminate entirely, it becomes less visible and impactful on print quality as device precision increases. Below are key causes and targeted solutions:

I. Core Causes of Pass-through

1. Excessively low printing feather value

2. Excessively high printing speed (especially in bidirectional mode)

3. Loose Y-axis drive belt (or insufficient lead screw lubrication)

4. Printhead abnormalities (e.g., ink breakage, clogging)

II. Targeted Solutions

Excessively low printing feather value UV inks have poor leveling and cure rapidly under UV exposure.

✅ Solutions:

Adjust the feather value to 80-100. This compensates for gaps via ink dot overlap, ensuring smoother pattern transitions.

Excessively high speed in bidirectional printing Bidirectional printing can amplify mechanical errors in the printhead’s reciprocating motion, with high speed exacerbating the issue.

✅ Solutions:

For high-precision needs: Switch to unidirectional printing (trading speed for accuracy).

For standard precision needs: Retain bidirectional printing but reduce speed appropriately.

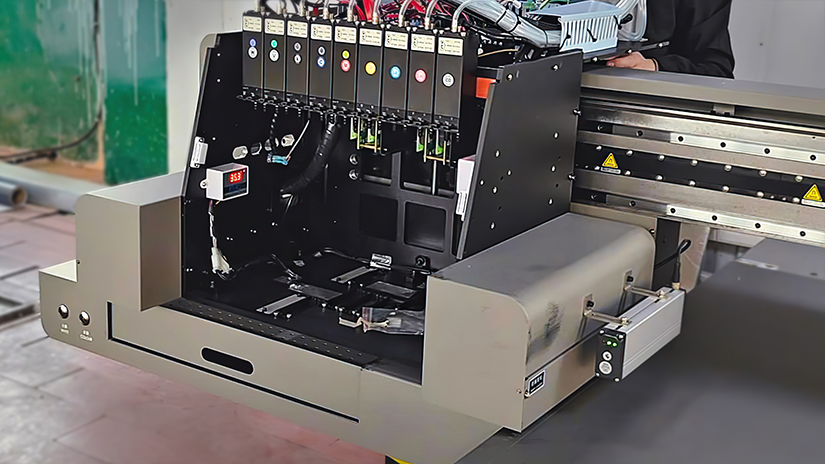

Loose Y-axis belt or lead screw drive issues

Long-term operation may loosen the Y-axis belt (causing unstable transmission) or leave lead screws under-lubricated (leading to jams).

✅ Solutions:

Belt-driven systems: Tighten the belt promptly and adjust tension.

Lead screw-driven systems: Regularly apply lubricant to maintain smooth operation.

Poor printhead condition or nozzle missing

Clogged printheads or uneven ink discharge directly cause intermittent print paths, resulting in obvious pass-through.

✅ Solutions:

Pause printing and clean the printhead with cleaning fluid until ink flows in a continuous, beaded stream (indicating unobstructed nozzles).

Daily maintenance: Print a test strip before daily operation to confirm the printhead is in normal condition.